Electronic Box Build Assembly

Enhancing Supply Chain & Manufacturing Control with Vertical Integration

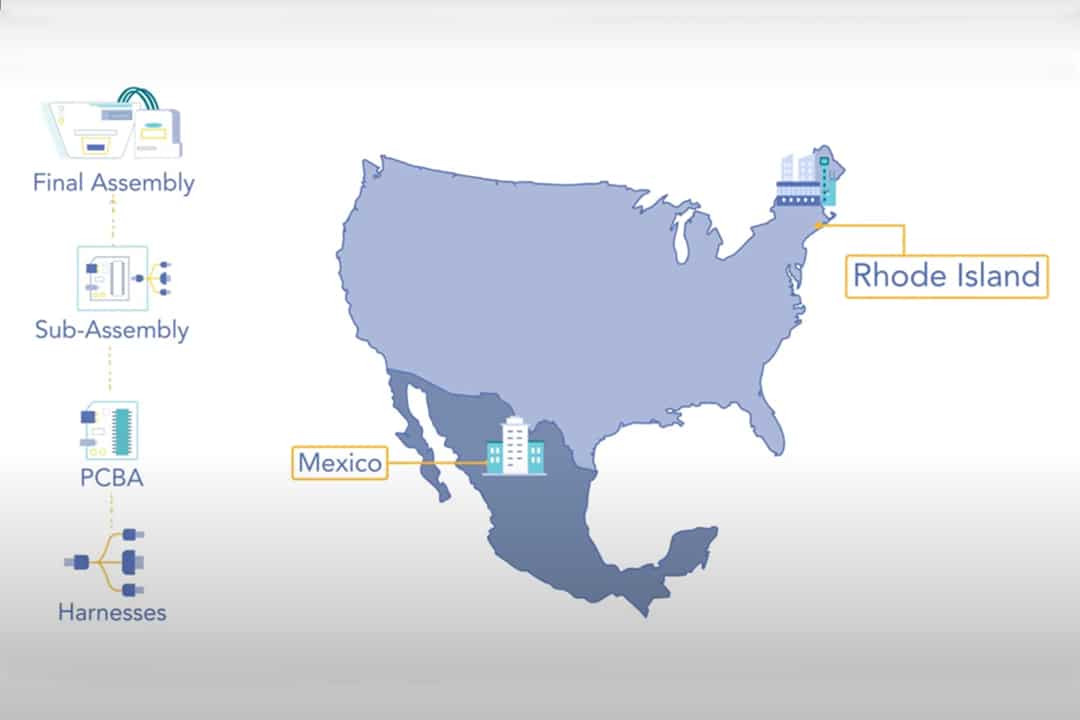

US-Mexico Hybrid Manufacturing Model Delivers Cost-Effective Solutions

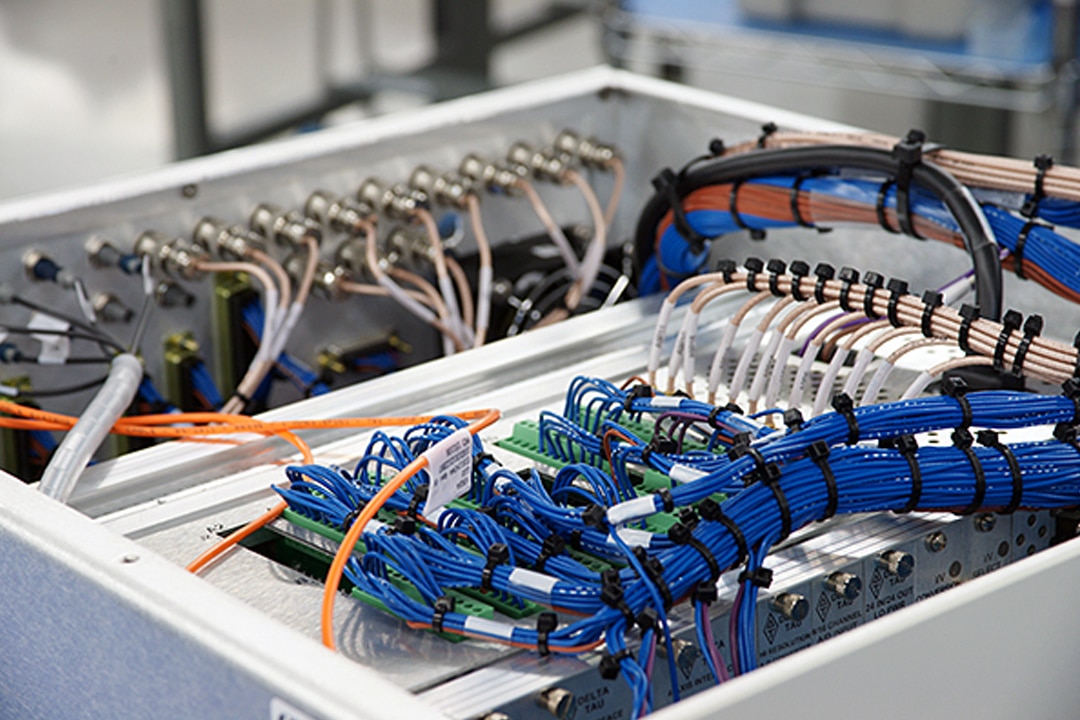

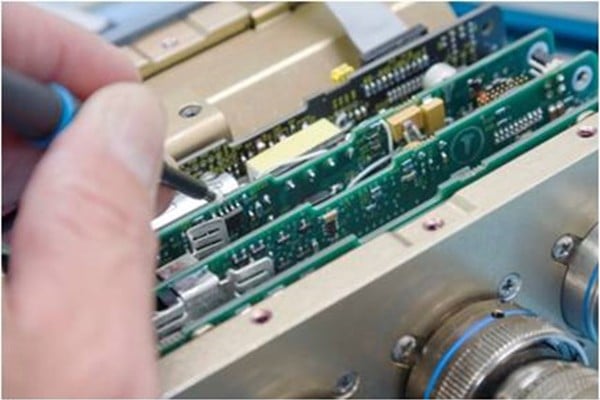

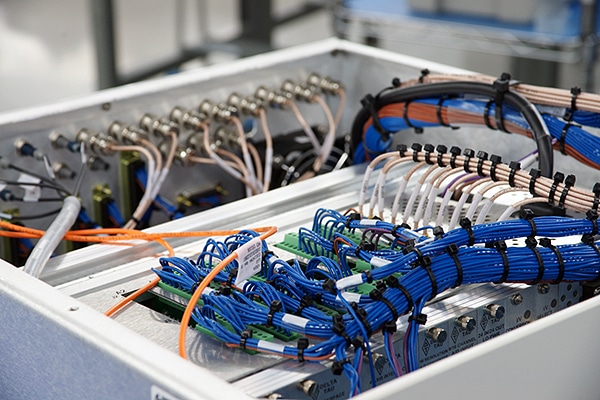

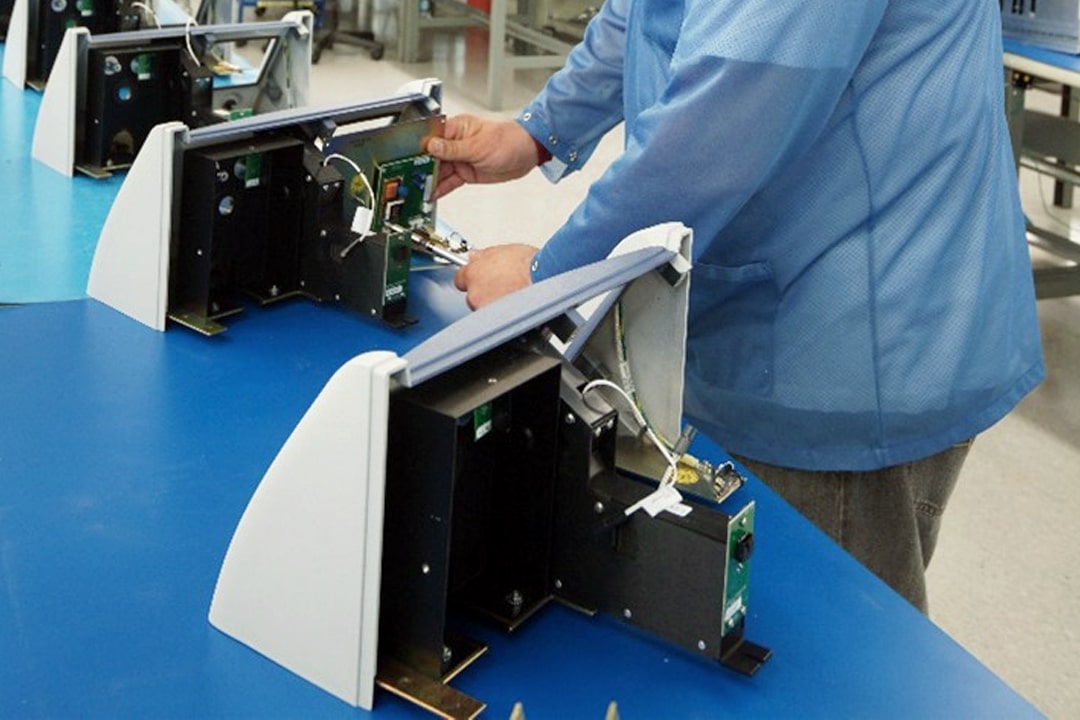

Many electronics manufacturing service providers specialize solely in printed circuit board assembly, cable assembly, or wire harnesses. At Federal Electronics, we possess the capability and experience to not only offer these services in-house, but also provide the integration of these lower-level assemblies into higher-level assemblies such as electronic controllers—all while managing a complex supply chain.

By leveraging a vertically integrated production model, with a dual manufacturing footprint in the US and Mexico, Federal Electronics offers a suite of electronics manufacturing services that rivals those of Tier 1 and 2 EMS providers. Our solutions are tailored for OEMs of high complexity, highly engineered, and highly regulated products, that may not have the annual spend or volume requirements to partner with larger contract manufacturers.

Federal Electronics Partnership Benefits

US-Mexico Footprint Provides Access to Low-Cost Region Pricing

Centralized IT System Connects Operations at Both Facilities for Seamless Performance

Our hybrid US-Mexico manufacturing model, with facilities in Rhode Island and Sonora, Mexico, is custom configured to address your unique requirements. Each site is fully capable of working either independently or in combination to deliver an optimal solution that delivers product where and when you need it with consistent quality and at a reduced cost.

Connected by a centralized IT system, raw material requirements, manufactured subassemblies, and finished product integration and test processes are fully managed by our ERP software. Material and labor allocations are captured by our nightly Material Requirements Planning and Scheduling modules, synchronizing resources at both sites daily with fresh information, and delivering consistent performance and quality at highly competitive pricing.

Vertical Integration Eliminates Margin Stack-Up

Reduced Cycle Times Deliver Accelerated Time-To-Market

Through our vertical integration model (which include cable assemblies, wire harnesses, and printed circuit board assemblies), Federal Electronics’ increases its influence over a larger portion of both the supply chain and manufacturing processes. Benefits include improved information flow both internally and externally, less exposure to supply chain disruptions, greater flexibility and responsiveness, enhanced supply chain coordination, and reduced cycle times. The net result is faster time-to-market, increased responsiveness to demand signals, and a highly cost-effective solution.

Engineering Support for DFx & Documentation Management

Vendor Problem Report Process Drives Accurate Product Specifications

Manufacturing engineers painstakingly review product documentation to identify opportunities for design changes that will reduce costs and manufacturing cycle times while improving yields and quality through the implementation of our DFx programs (Design for Manufacture and Assembly, Design For Test, and Design for Supply Chain).

Using our Vendor Problem Report process, documentation deficiencies are identified, tracked, and corrected during NPI or first article processes, ensuring your specifications accurately reflect the finished state of your electronic box build assemblies.

Custom Kanban Programs for JIT Delivery Improves Inventory Management

Dedicated Program Managers Ensure Project Success

Electronic box builds are great candidates for customized, 2-bin Kanban programs. Maintaining stock levels for both finished product and Federal-manufactured subassemblies (printed circuit board assemblies, cable assemblies, wire harnesses, card cages, etc.) based on bin size calculations increases throughput and compliance with your production forecasts while creating additional flexibility to respond to unplanned increases in demand.

Dedicated program managers at both plants enable Federal Electronics to administer Kanban programs that maximize inventory turns and deliver products to your Just-In-Time requirements.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.