Complex System Support

Customized Manufacturing Solutions for Complex Systems

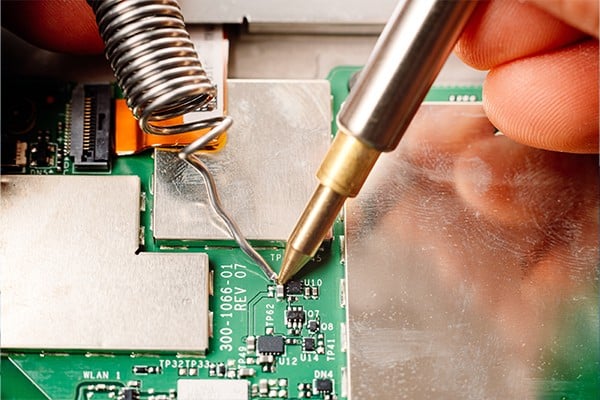

Federal Electronics specializes in delivering tailored electronics manufacturing solutions for large-scale capital equipment OEMs, particularly for complex, highly engineered, and heavily regulated products. Our comprehensive approach addresses the intricate challenges of manufacturing, configuration control, and supply chain management.

Understanding Your Requirements

Dedicated Team:

- Seamless Integration: Our dedicated team, led by an NPI/Transition Program Manager, draws from engineering, manufacturing, supply chain, and quality assurance disciplines, to become a virtual extension of your operation.

- US-Mexico Sourcing: Based on your product’s configuration, personnel from both our domestic and low-cost region facilities may be included in the team assigned to your project.

- In-Depth Analysis: We start by thoroughly understanding your project timeline, cost objectives, and technical requirements, which serve as the foundation for measuring our collaborative success.

Vertical Integration & Global Reach

Comprehensive Capabilities:

- Vertical Integration: We offer a range of electronics manufacturing capabilities including higher-level assemblies, industrial control panels, electronic box build assembly, electro-mechanical assemblies, precision mechanical assemblies, printed circuit board assemblies (PCBA), cable & wire harness assemblies, and fiber optic cable assemblies.

- Optimized Electronics Manufacturing: Higher labor content assemblies can be sourced from our Mexico facility either as finished products or as sub-assemblies for further integration at our US site.

- Global Supply Chain: Our global supply chain includes sources for custom fabricated metal parts, strategically located in close proximity to both our US and Mexico facilities.

- Effective Cost Management: Our global supply chain helps to reduce material costs, while our vertical integration model eliminates margin stack up.

Flexible Systems & Transparent Communication

Custom Configurations:

- Tailored Solutions: Our internal systems and processes are designed to be highly flexible and custom-configured to meet your unique requirements.

Centralized IT System:

- Integrated Operations: A centralized IT system connects engineering, supply chain, manufacturing, and quality operations across our domestic and lower-cost region sites, ensuring transparent communication throughout the process.

- Flexible ERP System: Our nightly MRP and finite scheduling modules provide near real-time information, while keeping our two facilities working in tandem.

Full Lifecycle Support

Comprehensive Services:

- NPI: During New Product Introduction (NPI), we apply DFx methodologies to improve manufacturability, increase yields, and optimize cost efficiency.

- Transition Management: For projects that are new to us but not new to you, we can help eliminate many of the typical challenges associated with moving from your current supplier or outsourcing from your internal operations, such as deficiencies in product documentation.

- Electronics Manufacturing: Our vertical integration model is designed to address the unique challenges associated with multi-layered, highly engineered, complex systems and allows for rapid response to dynamic schedule changes.

- Sustaining and Aftermarket: Established programs for repair, refurbishment, and component obsolescence management, help to satisfy your sustaining and aftermarket requirements.

Why Federal Electronics?

- Decades of Experience: With thousands of successful projects under our belt, we’ve expanded and refined our electronics manufacturing systems and processes to effectively address virtually any challenge you may encounter.

- Unmatched Expertise: We tackle challenges that other contract manufacturers can’t or won’t, building our reputation on delivering success.

- End-to-End Solutions: Comprehensive support through the entire product lifecycle.

- Flexible and Customizable: Systems and processes tailored to your unique needs.

- Global Supply Chain: Expertise in sourcing complex component parts in lower volumes.

- Seamless Integration: Dedicated team acting as a virtual extension of your operation.

- Transparent Communication: Centralized IT system ensures clear communication throughout the process.

- Cost Management: Selective utilization of our Mexico facility produces unprecedented and highly effective cost management for complex electronic products.

- Centralized ERP System: Our nightly MRP and finite scheduling modules provide near real-time information, while keeping our two facilities working in tandem.

Partner with Federal Electronics

Overcome your most critical manufacturing challenges and contact us today to learn more about our customized solutions.