Mission Critical Support

Ensuring Compliance in Highly Regulated Markets

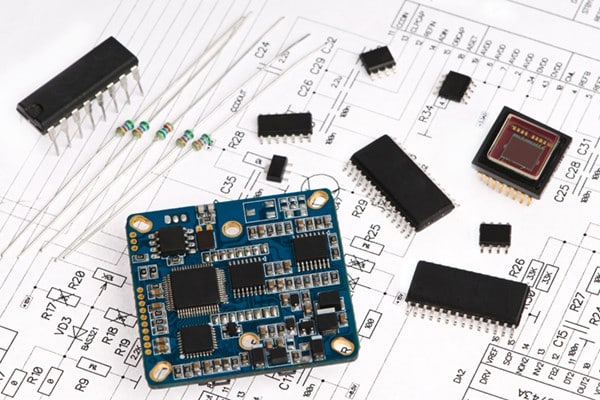

Federal Electronics specializes in delivering electronics manufacturing solutions for companies in highly regulated and specialized markets, such as military, aerospace, medical and industrial sectors. Our expertise ensures compliance with stringent regulatory standards and addresses the unique challenges of complex, highly engineered, mission critical products.

Meeting Stringent Standards for Mission Critical Applications

Understanding Complex Requirements:

- No Room for Failure: For mission critical applications, the standard is simple: the system must work the first time, every time. Process development includes consideration for testing, inspection parameters, gap analyses, poke-a-yoke, and statistical techniques to design processes that mitigate the potential for error during manufacturing.

- Thorough Analysis: We conduct detailed gap analyses to understand and document requirements that exceed conventional standards, including those specific to customer or program needs, such as advanced weapons systems and medical devices.

- Program-Specific Quality Policies: Requirements are captured in program-specific quality policies and integrated into our process documentation and quality control plans.

- Robust QMS: All activity is conducted under the umbrella of our AS9100, ISO13485, and ISO9001 registered Quality Management System.

Innovative Solutions & Robust Traceability

Creative Problem-Solving:

- New Processes and Modifications: We introduce and validate new processes or modify existing ones using Manufacturing Process Control Procedures (MPCPs).

- Comprehensive MPCPs: These procedures cover equipment requisites, process instructions, critical characteristics, training criteria, and raw material specifications, serving as primary governing documents.

Detailed Recordkeeping:

- ERP MES Systems: Our systems capture and monitor key data points, including manufacturing dates, operators, tooling details, and lot codes for raw materials and end products.

- Compliance Data: We work closely with clients from program inception to provide the necessary data for compliance demonstration.

Why Federal Electronics?

- Decades of Experience: Leveraging decades of experience, we guarantee full compliance by thoroughly understanding customer requirements and executing disciplined processes.

- Unmatched Expertise: We tackle challenges that other contract manufacturers can’t or won’t, building our reputation on delivering success.

- End-to-End Solutions: Comprehensive support from product launch through aftermarket services.

- Flexible and Customizable: Systems and processes tailored to your unique needs.

- Global Supply Chain: Expertise in sourcing complex component parts in lower volumes.

- Seamless Integration: Dedicated team acting as a virtual extension of your operation.

- Transparent Communication: Centralized IT system ensures clear communication throughout the process.

- Cost Management: Selective utilization of our Mexico facility produces unprecedented and highly effective cost management for complex electronic products.

- Centralized ERP System: Our nightly MRP and finite scheduling modules provide near real-time information, while keeping our two facilities working in tandem.

Partner with Federal Electronics

Overcome your most critical manufacturing challenges and contact us today to learn more about our customized solutions.