Service Capabilities

Developed For Your Critical Challenges

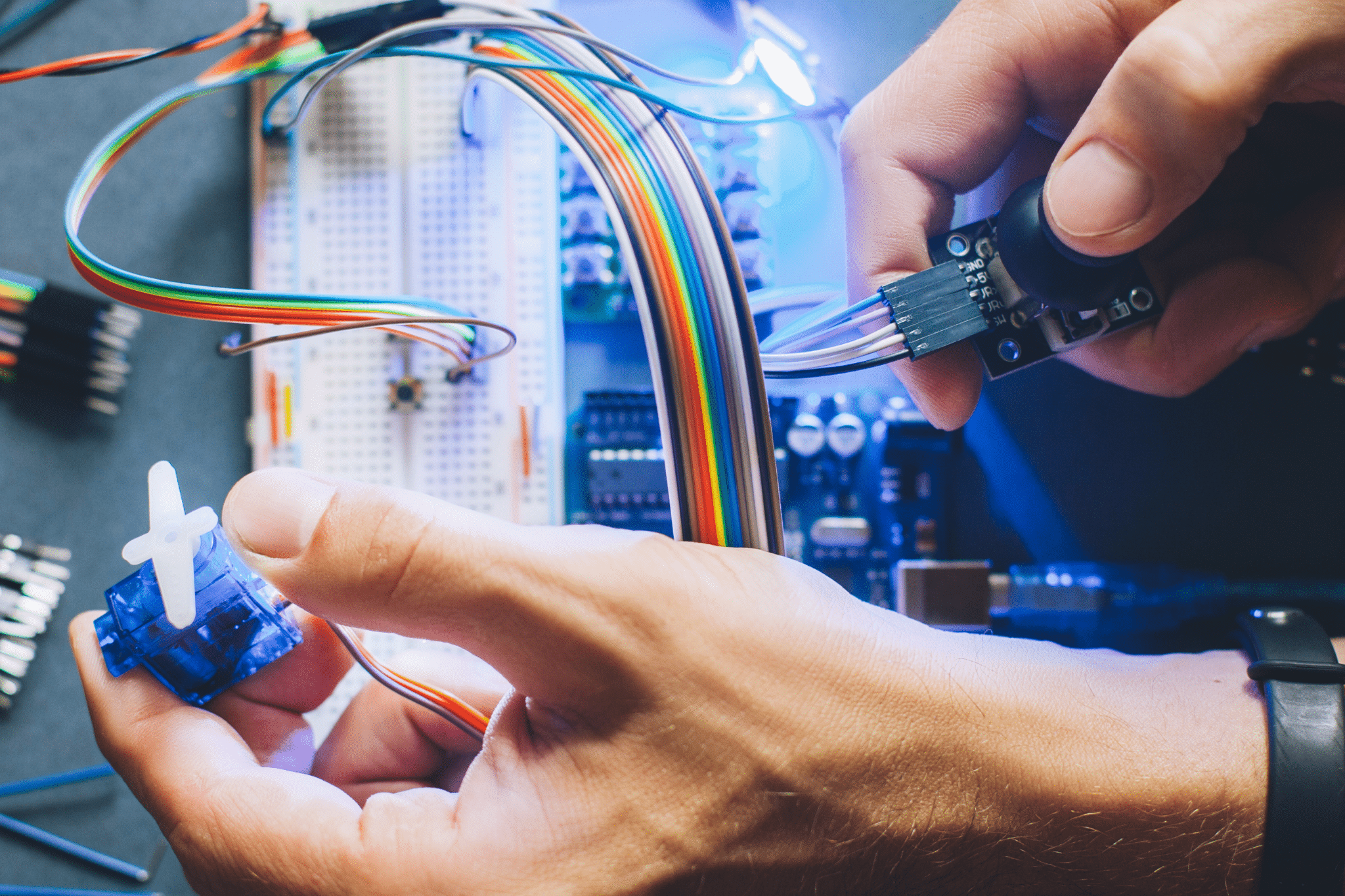

New Product Introduction (NPI)

Rapidly Taking Your Ideas to Market

Our New Product Introduction (NPI) methodology is designed to move as rapidly and seamlessly as possible, from prototype, through NPI, to scaled manufacturing. Our decades of electronics manufacturing experience have taught us the importance of a dedicated project launch team, focused on your budget and your deadline, working closely with your staff to make your new product a reality.

Supply Chain & Logistics

Flexible, Integrated Supply Chain for Cost-Competitive Advantage

In today’s competitive global marketplace, OEMs must have the right product available at the right time to avoid losing market share to more agile competitors. Factors such as higher inventory turns, shorter product life cycles, and increased expectations for agility make a flexible and scalable integrated supply chain essential for success. Federal Electronics’ supply chain and logistics services provide the necessary flexibility and scalability to meet these demands, ensuring that your products are delivered efficiently and cost-effectively.

Material Requirement Planning

Resource and Constraint Management

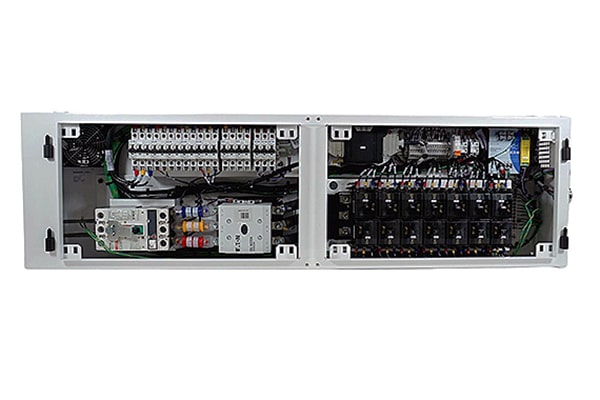

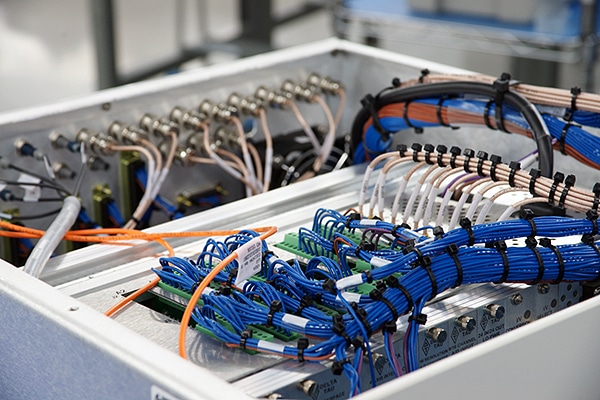

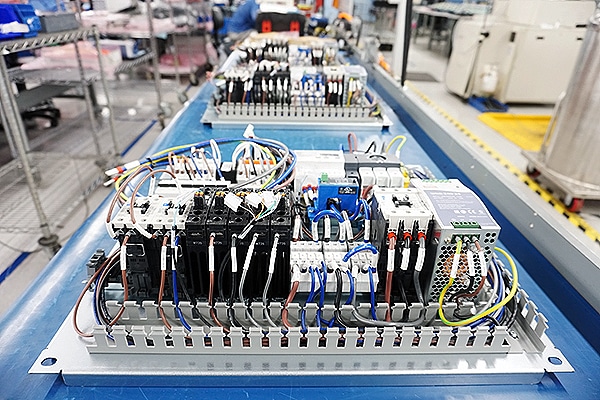

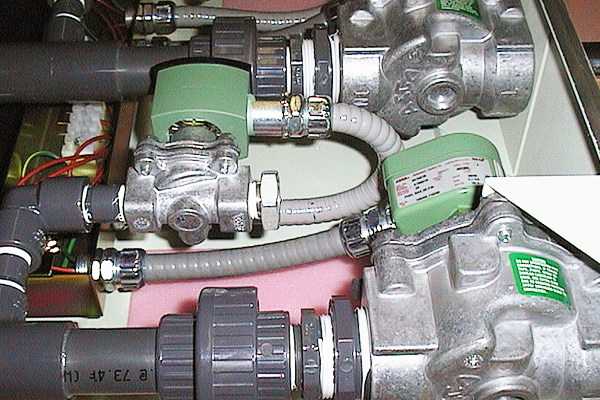

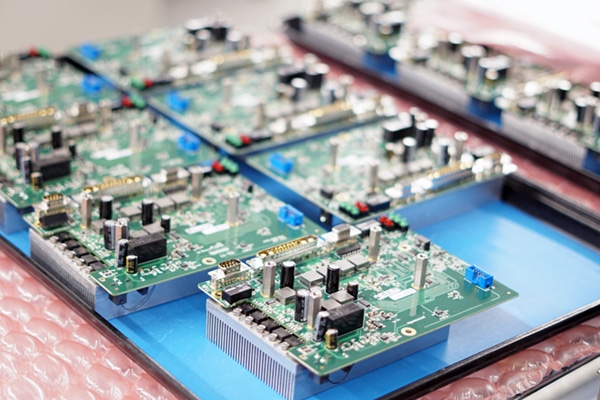

Manufacturing Services

Specialized Capabilities for Higher Complexity, Highly Regulated Products

Federal Electronics offers a vertically integrated model with expertise in a wide range of electronics manufacturing capabilities. Our services are designed to address the unique challenges associated with multi-layered, highly engineered, complex systems and allows for rapid response to dynamic schedule changes. Higher labor content assemblies can be made in our Mexico facility either as finished products or as sub-assemblies for further integration at our US site.

Sustaining Services

Support Throughout Your Product’s Entire Lifecycle

Aftermarket support is often unpredictable and difficult to forecast. Federal Electronics provides flexible and comprehensive services that extend the life of your products until your customers are ready to move on to the next generation.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.