Our Solutions

Your Strategic Advantage

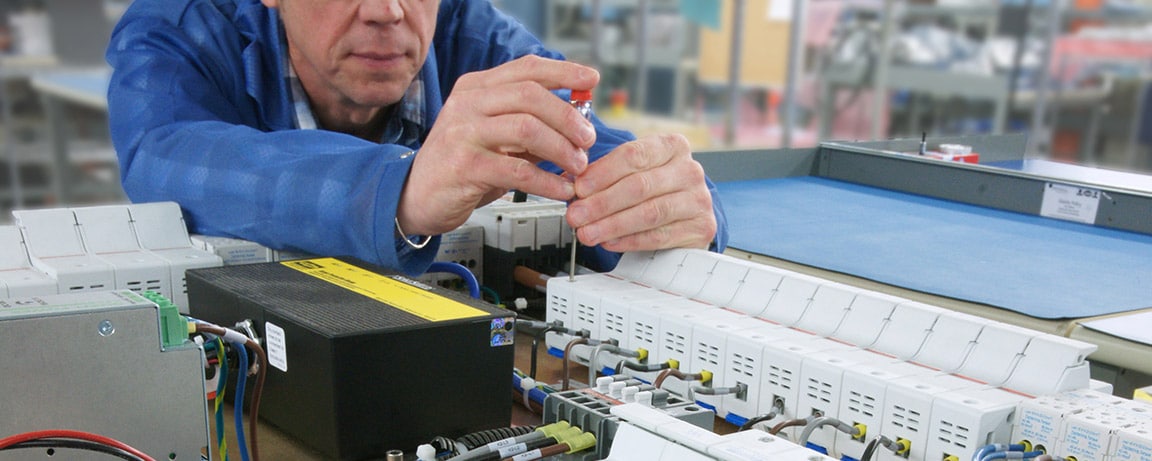

Focused Support for Your Electronics Manufacturing Requirements

Navigating the world of electronics manufacturing unveils a landscape fraught with challenges. We are here to simplify those challenges, so you can focus on delivering success.

Complex System Support

Customized Manufacturing Solutions for Complex System

Federal Electronics specializes in delivering tailored electronics manufacturing solutions for large-scale capital equipment OEMs, particularly for complex, highly engineered, and heavily regulated products. Our comprehensive approach addresses the intricate challenges of manufacturing, configuration control, and supply chain management.

- Understanding Your Requirements

- Vertical Integration & Global Reach

- Flexible Systems & Transparent Communication

- Full Lifecycle Support

- Why Federal Electronics?

Dedicated Team:

Comprehensive Capabilities:

Custom Configurations:

Centralized IT System:

Comprehensive Services:

Partner with Federal Electronics and overcome your most critical manufacturing challenges.

Contact us today to learn more about our customized solutions.

Product Launch/ Transition Management

Accelerating Your Time to Market

Federal Electronics’ Product Launch and Transition Management Solution offers OEMs of complex, highly engineered products a comprehensive suite of services designed to speed up market entry and ensure consistent, reliable electronics manufacturing.

- Project Management

- Vertical Integration

- IT & Engineering Integration

- Specialized Supply Chain Network

- Why Federal Electronics?

Initial Engagement:

Transparency and Accountability:

Centers of Competency:

Centralized IT System:

Proactive Issue Resolution:

Custom Fabricated Parts:

Partner with Federal Electronics for your product launch and transition management needs.

Contact us today to learn more about our solutions strategies.

Mission Critical Support

Ensuring Compliance in Highly Regulated Markets

Federal Electronics specializes in delivering electronics manufacturing solutions for companies in highly regulated and specialized markets, such as military, aerospace, medical and industrial sectors. Our expertise ensures compliance with stringent regulatory standards and addresses the unique challenges of complex, highly engineered products.

Understanding Complex Requirements:

Creative Problem-Solving:

Detailed Recordkeeping:

Partner with Federal Electronics for exceptional value and guaranteed compliance in your mission-critical applications.

Contact us today to learn more about our specialized solutions.

US-Mexico Sourcing

Overcoming Challenges in Cost Management

OEMs of higher complexity and highly engineered capital equipment, particularly in heavily regulated industries, face significant challenges in achieving meaningful cost reductions without absorbing considerable risk. Sourcing concessions from component suppliers has its limits. Additionally, finding reliable offshore contract manufacturers with the necessary qualifications and infrastructure is a formidable task.

Federal Electronics’ US-Mexico Sourcing model leverages the synergies of our Cranston, RI, and Hermosillo, Sonora, Mexico facilities to deliver the most cost-effective solutions for your product requirements.

Tailored Sourcing Solutions:

Ideal Candidates:

Our Mexico facility provides significant logistical benefits, especially for OEMs in the Midwest and West Coast regions.

Centralized IT System:

The Federal Advantage

Our hybrid model combines domestic and nearshore facilities, creating opportunities for cost reduction, increased efficiency, and risk mitigation. By focusing on labor content instead of volume, Federal Electronics delivers cost-effective, compliant solutions for OEMs of complex, highly engineered products.

Experience the benefits of our innovative sourcing model and achieve significant cost reductions without added risk. Contact Federal Electronics today to learn more.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.