Industries

Different Markets with Common Challenges

While our customers come from diverse industries, they all share a common thread…

That thread is the need to execute an outsourcing strategy that eliminates risk and enhances their ability to service their customers in a low-to-mid volume, high mix, and high complexity environment. While sharing many common challenges, OEMs in military, medical and high-end industrial markets also face unique market specific regulations. At Federal Electronics, we account for these requirements within a custom configured suite of solutions and services designed with each customers’ particular interests in mind.

Aerospace & Defense

Manufacturing Expertise for Military Contractors

When lives are on the line, systems have to work the first time, every time. Federal Electronics is an EMS provider whose AS9100 registered facility has the experience delivering complex assemblies to the demanding specifications of military contractors and aerospace manufacturing clients.

Aerospace & Defense Manufacturing Applications

Our Experience as a Trusted Supplier to Defense Contractors

Cybersecurity and Protection of Confidential Unclassified Information (CUI)

Compliance with cybersecurity requirements is not merely a matter of regulatory adherence, but a fundamental necessity for safeguarding Controlled Unclassified Information (CUI). Federal Electronics is committed to upholding the highest cybersecurity standards as required by DFARS to ensure the confidentiality, integrity, and availability of CUI.

Federal Electronics is compliant with the NIST Special Publication 800-171 (NIST SP 800-171).

Further, we are proactively working towards certification under the Cybersecurity Maturity Model Certification (CMMC) framework.

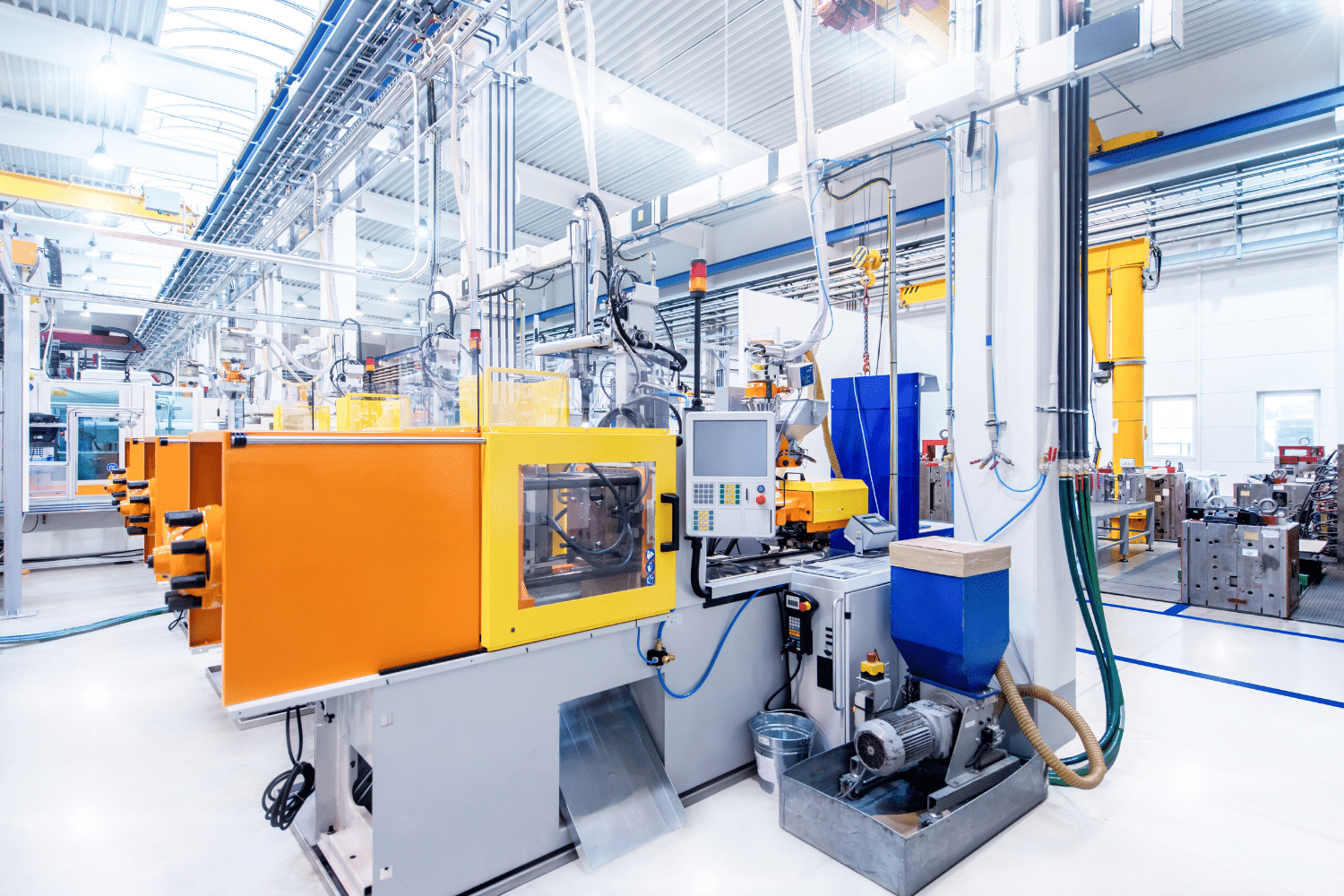

Industrial

Serving the needs of capital equipment OEMs

The electronics manufacturing industry covers a wide variety of diverse segments, such as factory automation, material processing, semiconductor capital equipment, and robotics. While product types and complexity can differ greatly, most OEMs are faced with similar challenges, including increased pressure to reduce costs and decrease time-to-market while managing high rates of product change. Federal Electronics’ ISO 9001:2015 registered industrial electronics manufacturing services, ensure that product is delivered on time and to your specifications. As your manufacturing partner, our suite of solutions and services help to minimize your total liability and maintain the flexibility to adjust to volatile demand requirements.

Industrial Manufacturing Applications

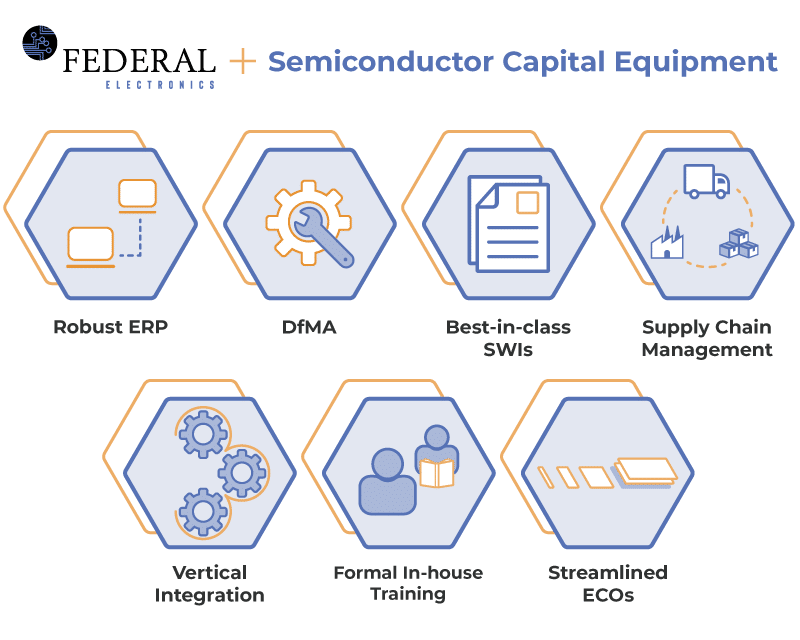

Semiconductor Capital Equipment

A High Standard of Quality is Fundamental to Our Culture

With the demand for silicon chips proliferating, reaching an all-time high, supply chains across the world are strained to keep pace. Semiconductor Capital Equipment OEMs, in particular, are in great need of electronics contract manufacturers that can meet their challenging demands while navigating continuous supply chain disruptions. With material availability in a Catch-22 (chips that are experiencing shortages are needed to make the machines to make the chips), it is more important than ever to have suppliers that can respond rapidly to material disruptions while scaling successfully to meet increasing demand.

Semiconductor Capital Equipment Manufacturing Applications

Medical

Medical Equipment Manufacturing Expertise

Life science and medical equipment manufacturers face daunting challenges to provide reliable, highly complex medical electronics systems to stringent quality and regulatory standards while participating in a fiercely competitive industry. As an ISO 13485 registered medical device contract manufacturer, Federal Electronics offers a variety of medical electronics manufacturing services. Our experience serving the life sciences industry ensures the cost-effective, rapid deployment of new products, produced in a highly controlled environment, with the flexibility to adjust to fluctuating demand requirements.

Medical Manufacturing Applications

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.