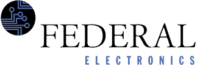

7 Methods to Handle Material Shortages

The electronics industry is notorious for year-round supply chain challenges due in large part to component obsolescence. However, today’s leading cause of disruption stems from unprecedented material shortages caused by a perfect storm of pandemic-related supply constraints and rapidly increasing demand from a vast number of new technologies.

The impact to OEM’s is significant – production plants being shut down, delayed product launches, and increasingly long lead times for end customers – all of which are directly affecting bottom lines.

It has never been more critical to have a manufacturing partner that navigates these challenges proactively, creatively, and with the sense of urgency needed for a significant advantage in competitive markets.

Our Approach

A successful supply chain management strategy is empowered through the disciplined use of leading technology with automated communication from an ERP system.

Proper use of this technology, along with a relentless commitment to customer success, sets Federal Electronics apart from other contract manufacturers, particularly during times of unprecedented material shortages.

1. Rapidly React to Customer Demand

Whether it’s processing a new purchase order or a request to expedite, no time can be wasted in communicating new demand throughout the supply chain in order to immediately secure the material. With the right technology and a sense of urgency, all material orders can be placed throughout the supply chain within 24 hours with no limit on the number of components in the bill of material.

Recognizing that changes often occur to existing orders, driven by variability in both supply and demand, the Federal Electronics ERP system runs daily to ensure material orders and production schedules are constantly optimized to meet customer demand.

2. Actively Seek Forecasts

Any information on forecasted demand can help the supply chain anticipate market needs and plan accordingly. Rather than processing a PO and moving on, a proactive contract manufacturer requests an extended forecast from the customer and follows up accordingly.

Extended forecasts must also be actionable while maintaining a careful balance of material security and material liability. Federal Electronics can execute material liability agreements to ensure an optimal level of stock is secured without subjecting customers to excessive material commitments.

Once forecasts are received, the Federal Electronics team goes above and beyond by spot-checking them for potential errors. This includes cross-referencing the forecasted demand with prior conversations and ensuring that the information aligns with existing orders.

3. Identify Potential Problems

Not knowing what you don’t know is perhaps the greatest source of anxiety in managing a supply chain. Unfortunately, material liability agreements and executed purchase orders can only go so far in preventing business-altering delivery delays. This is particularly true for cases in which suppliers and subcontractors fail to notify buyers of production setbacks.

Identifying potential problems, like historically unreliable vendors, and creating mitigation plans in advance, can be the difference in delivering finished goods on time or having an order cancelled. By covering blind spots and taking preventative action, future time spent putting out fires can also be easily averted.

With over 70 years of experience and millions of different components purchased, Federal Electronics can easily identify these risks and recommend the best mitigation plans. Actions typically include:

- Selecting primary, secondary, and tertiary sources for essential material

- Identify and qualify suitable alternates for high-risk components

- Create bonding agreements with material vendors

- Acquire all forecasted needs immediately

- Assist suppliers in how they plan to manage stock

4. Provide Supply Chain Visibility

End customers need full transparency when supply chain issues are not quickly resolved. This improves collaboration and allows for potential production scheduling changes to take place. Through the use of sophisticated technology, lead time changes from material suppliers can automatically update ERP systems allowing for near real-time alerts to end customers.

With an ERP that runs daily, new problems can be escalated within 24 hours. Changes, such as cancelling orders with primary suppliers in favor of secondary sources, for example, are then executed within the same day.

5. Get Creative

Accessing material in dire situations often requires thinking outside the box. This includes increasing access to supply by looking into new regions, identifying new substitute material, or approaching a larger network of vendors for assistance.

With a relentless commitment to customer success, the Federal Electronics team leaves no stone unturned. All options are exhausted with the urgency necessary to find a suitable solution to customer needs.

6. Ensure Action is Taken

A plan is only as good as its execution. No time can be wasted when material availability can change within seconds. Therefore, a contract manufacturer must hold all stakeholders accountable for executing assigned action items on time.

Understanding that customers may have competing priorities, continuous follow ups from the Federal Electronics team helps to ensure that nothing falls through the cracks.

7.Consider Reputable Brokers

Recognizing that this may not always be an acceptable option, it can sometimes be the last hope in preventing other more severe consequences from material scarcity.

Brokers always carry some degree of risk in counterfeit components. However, with the right anti-counterfeit programs, this risk can be properly mitigated to an acceptable level depending on the circumstances.

Moreover, having a large network of Brokers with a long history of business helps in identifying Brokers with the lowest level of risk. Federal Electronics can help navigate this challenging process while ensuring competitive pricing is found through multiple bids.

Conclusion

The severe ramifications arising from material shortages are not inevitable. With the right partner, these situations can be handled before they impact your bottom line.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.