Military & Defense

AS9100 Facility Supports Mission Critical Applications

Vertical Integration Model Reduces Sourcing Complexity

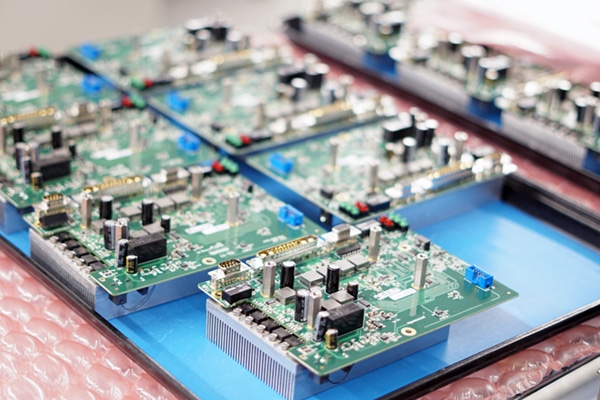

When lives are on the line, mission critical applications for military and defense electronics systems must work the first time, every time. As a leading military electronics manufacturer, Federal Electronics ISO 9001 and AS9100 facility possesses the requisite processes and controls to meet the demanding requirements of our defense customers, from the prime contractor level down to their sub-tier partners.

For over 30 years, Federal Electronics has delivered administrative, engineering, supply chain, and manufacturing services designed for the unique challenges associated with higher mix, lower volume, highly engineered military electronics products. Our vertical integration model supports the diverse sourcing strategies of today’s defense electronic manufacturers, from printed circuit board assembly (PCBA), cable assembly and complex wire harness assembly, to ruggedized industrial control panels, electronic box build assembly, and large scale higher level assemblies.

Market Segments

Military Electronics Manufacturing Applications

- Missile navigation and guidance

- Unmanned ground vehicles and robotics

- Amphibious transport ships

- Shipboard radar systems

- Joint Strike Fighters

- Unmanned underwater vehicles

- Ballistic missile systems

- Theater surveillance

- Secured communications

Federal Electronics Partnership Benefits

Vertical Integration For Supplier Rationalization

Integrated Military Electronics Manufacturing Solution Eliminates Margin Stack up

Federal Electronics vertical integration model enables defense contractors to right-size their supply chain. Federal’s military electronics manufacturing services include cable assembly, wire harness assembly, printed circuit board assembly (PCBA), electronic box build assembly, and electro-mechanical assembly, offered individually or as part of our integrated electronic manufacturing solution.

This vertical integration increases our influence over a larger portion of both the supply chain and manufacturing processes while eliminating margin stack up. Benefits include improved information flow both internally and externally, less exposure to supply chain disruptions, greater flexibility, responsiveness and schedule protection, enhanced supply chain coordination, and more effective project risk management.

The net result is mission critical military electronics products delivered on budget, on time, and to your specifications as part of a highly cost-effective outsourced solution.

Supply Chain Support For Complex Military Products

Ensuring a Flexible and Reliable Supply Chain

Complex military electronics products consisting of multi-level Bills Of Material can pose difficult supply chain challenges due to stringent specifications and regulatory compliance, longer lead times, and component obsolescence, especially for legacy programs.

Federal Electronics’ supply chain support for complex military electronic manufacturing projects includes full lifecycle management, a responsive and highly qualified network of custom fabricated metal products, and by virtue of our vertical integration model, strategic relationships with suppliers throughout the military electronics supply chain.

Raw material requirements, manufactured sub-assemblies, and finished product integration and test processes are fully managed by our ERP system. Material and labor allocations are captured by our nightly Material Requirements Planning and Finite Scheduling modules, synching resources with fresh information and delivering consistent performance by ensuring a flexible and reliable supply chain.

AS9100 Quality Management System Supports Defense Regulations

Building In Quality With Design For Excellence Services

Delivering products that work the first time, every time requires a tenacious drive for excellence and a culture that expects continuous improvement in everything we do. Our AS9100 registered Quality Management System ensures that we apply a disciplined approach to every facet of our operation in accordance with the rigid expectations of our military electronics customers.

Exceptional quality performance for defense electronics used in mission critical applications requires careful planning and attention to detail, and that starts with our Design For Excellence services. Whether the product is new to you (NPI) or just new to us (re-sourced), our engineers will painstakingly review product documentation to identify opportunities for product improvements that will reduce costs and manufacturing cycle times while improving yields and quality.

Cybersecurity and Protection of CUI

Continually Improving Our Security Posture In Response To Evolving Threats

Compliance with cybersecurity requirements is not merely a matter of regulatory adherence, but a fundamental necessity for safeguarding Controlled Unclassified Information (CUI). Federal Electronics is committed to upholding the highest cybersecurity standards as required by DFARS to ensure the confidentiality, integrity, and availability of CUI.

Federal Electronics is fully compliant with the NIST Special Publication 800-171 (NIST SP 800-171) requirements.

Further, we are proactively working towards certification under the Cybersecurity Maturity Model Certification (CMMC) framework.

Quality Standards & Certifications

Raytheon 4 Star Supplier Excellence Award

contributions increase our competitiveness and our results.“

Our Experience as a Trusted Supplier to Defense Contractors

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.