Industrial Control Panel Manufacturing

UL 508a Certified Industrial Control Panels with Federal Electronics

Vertical Integration and US-Mexico Manufacturing Sites Deliver Cost Effective Solutions

If you are in need of a supplier-partner that is UL 508a compliant, actively contributes to your cost reduction strategy, and works to accelerate your product’s time to market, then Federal Electronics is the choice for Industrial Control Panel manufacturing.

For over 60 years, Federal Electronics has provided OEMs of high complexity, highly engineered, and highly regulated products with cost-effective integrated electronic manufacturing solutions. Our UL 508a certified facilities have the resources and experience to support your industrial control panel projects with a dedicated team of engineering, manufacturing, quality and supply chain professionals focused on your success.

Federal Electronics Partnership Benefits

UL 508a Certification with a US and Mexico Manufacturing Footprint

Blended Manufacturing, Engineering & Supply Chain Services to Optimize Your Industrial Control Panel Solution

As a UL 508A certified build-to-print industrial control panel manufacturer, Federal Electronics leverages its vertical integration capabilities and domestic/nearshore manufacturing sites to deliver cost effective solutions to OEMs of complex and highly engineered capital equipment. Having both our US and Mexico sites certified to this industry standard enables Federal Electronics to offer a suite of customized solutions that can be uniquely configured to address your specific challenges.

While our Mexico facility is the obvious choice if cost reductions are your priority, our US site is best for military/defense applications or if compliance with regulations such as the Build America Buy America Act are required.

Those looking for a blended approach can choose to have labor intensive subassemblies produced at our Hermosillo facility and then shipped to Cranston, Rhode Island for final integration and test. Dedicated program managers at both plants enable Federal Electronics to support Kanban programs that maximize your inventory turns and Just-In-Time (JIT) requirements, especially when product coming from Mexico is destined for the Western half of the United States.

Design For Excellence: Optimizing Quality, Cost, and Process Control

Experience the Benefits of Our Vertical Integration Services

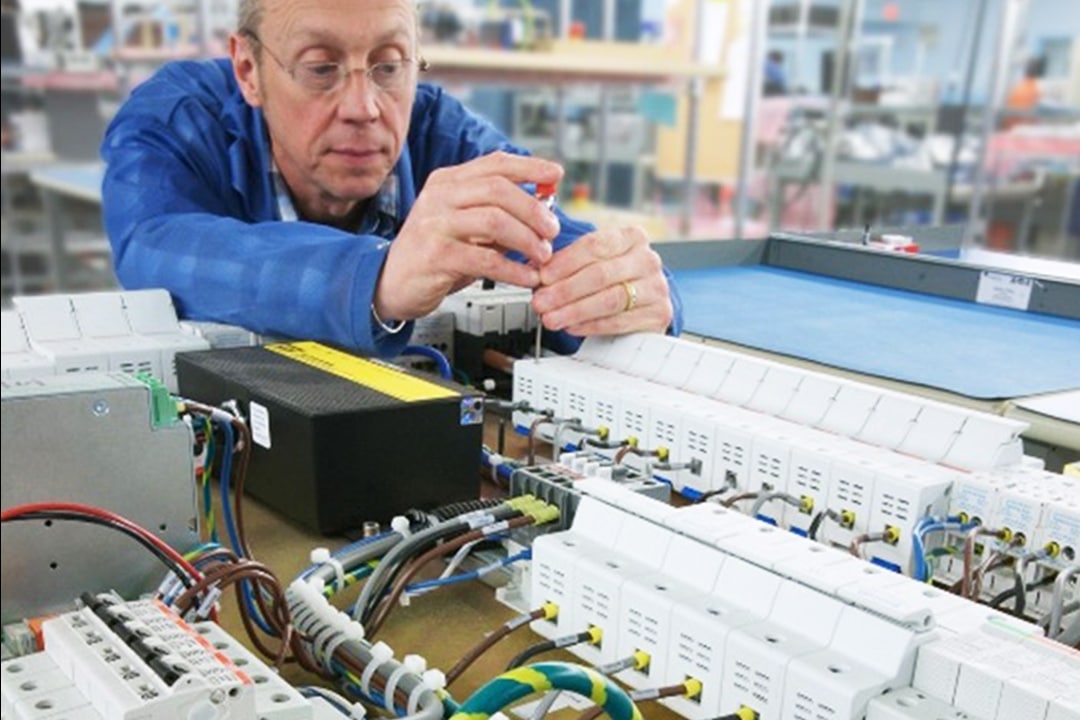

Federal Electronics applies Design For Excellence principles to streamline processes, reduce costs, and improve quality and repeatability. Incorporated during the design review and prototyping stages, Design for Assembly, Design for Test, and Design for Supply Chain evaluations can identify potential issues before they become costly problems.

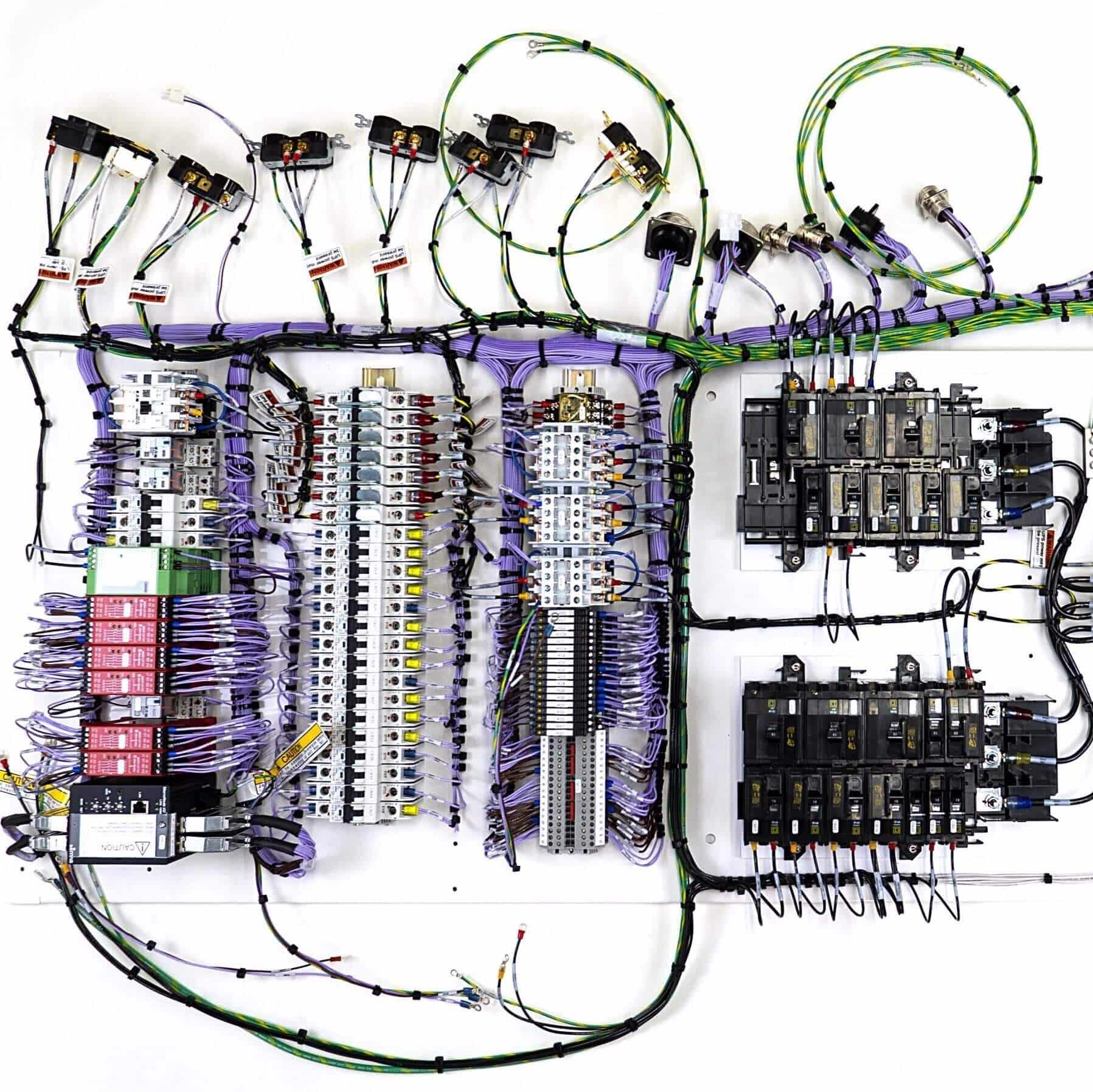

While common industry practice utilizes discrete wires for electrical panel assembly, Federal Electronics’ vertical integration capabilities translate those point-to-point schematics into pre-tested custom cable assemblies and wire harness assemblies, reducing overall labor content and cost, increasing throughput, and ensuring process consistency.

Stringent quality control procedures include final product inspection and test protocols that support your most critical requirements, including those associated with “Copy Exact” standards.

Reduce Costs and Accelerate Time-to-Market

Improving Your Competitive Position

Federal Electronics contributes to your cost reduction strategies during the design phase and throughout the product’s life cycle. Critical activities include influencing the design to accommodate the most efficient production processes, selection of standardized components to leverage total demand, and consolidation of the supply base. This serves to simplify the pipeline, increase buying power, and negotiate more attractive terms and conditions.

Accelerating time-to-market requires close collaboration between Federal’s engineering, manufacturing, and supply chain professionals, as well as your design engineers. Collaboratively, we are able to focus on agile prototyping and design feedback, integrating suppliers into the design process, and employing concurrent engineering activities where design, manufacturing, and testing run in parallel rather than sequentially.

Support from NPI Through Scaled Production Volumes

Consistent and Reliable Performance

Our centralized IT system serves to effectively link manufacturing engineering, supply chain, and production teams at both facilities. A New Product Introduction Program Manager coordinates all activity to drive cost and inefficiency out of your control panels through the use of established Design For Excellence (DFx) methodologies that address manufacturing, test, and supply chain elements.

Once First Articles are approved, the project will transfer to one of our Sustaining Program Managers, who will become your primary point of contact and assume responsibility for managing your account.

Raw material requirements, manufactured subassemblies, and finished product integration and test processes are fully managed by our ERP system. Material and labor allocations are captured by our nightly Material Requirements Planning and Scheduling modules, synchronizing resources at both sites with the most current information to deliver consistent performance and quality at highly competitive pricing.

Proactive Supply Chain Management

Ensuring Continuity for a Flexible and Reliable Supply Chain

Our vertically integrated manufacturing services increase our influence over both the supply chain and manufacturing processes for common industrial control panel content, reducing cycle time and eliminating margin stack-up to provide a more responsive and cost-effective solution.

Federal Electronics’ supply chain professionals collaborate with supplier-partners early in the design process to reduce lead times, employ Just-In-Time (JIT) principles, and minimize the impact of directed source/sole source components. This allows us to leverage our relationships with supplier-partners to obtain the most competitive pricing and favorable terms.

Further opportunities for cost reduction are realized through the introduction of our approved Mexico supplier-partner network for custom fabricated, build-to-print sheet metal and cabinet enclosures.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.