Electro-mechanical Assembly Manufacturing

Specialized Process and Custom Test Solutions for Precision Assemblies

Extensive Supplier-Partner Network for Custom, Build-To-Print Precision Machined Parts and Sheet Metal

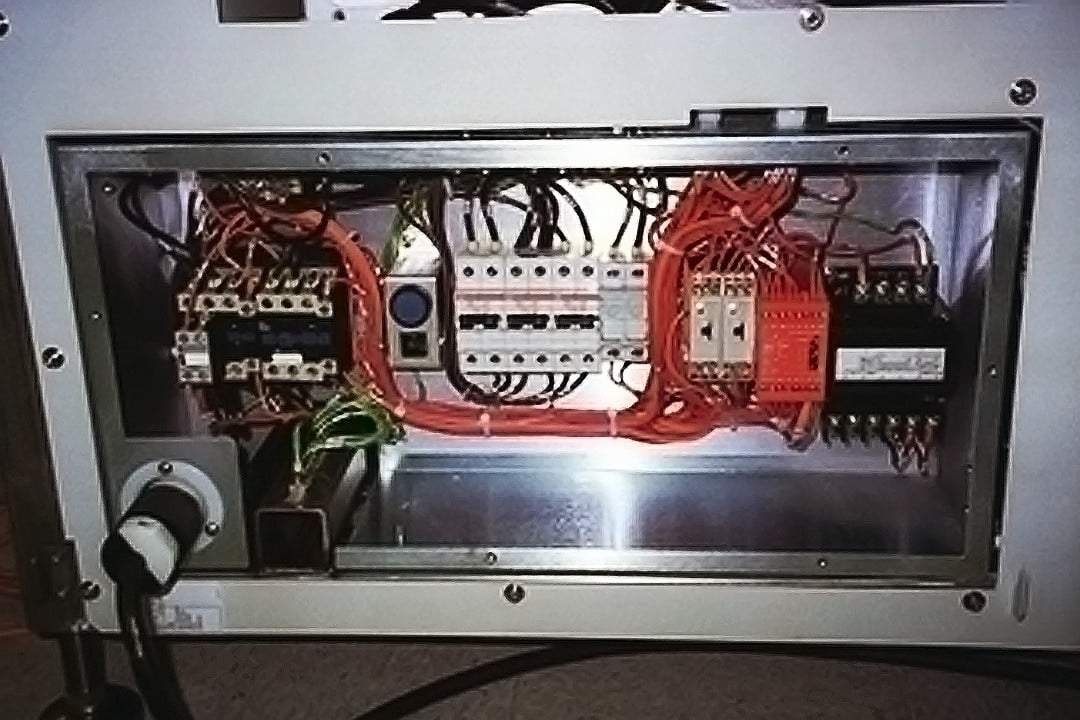

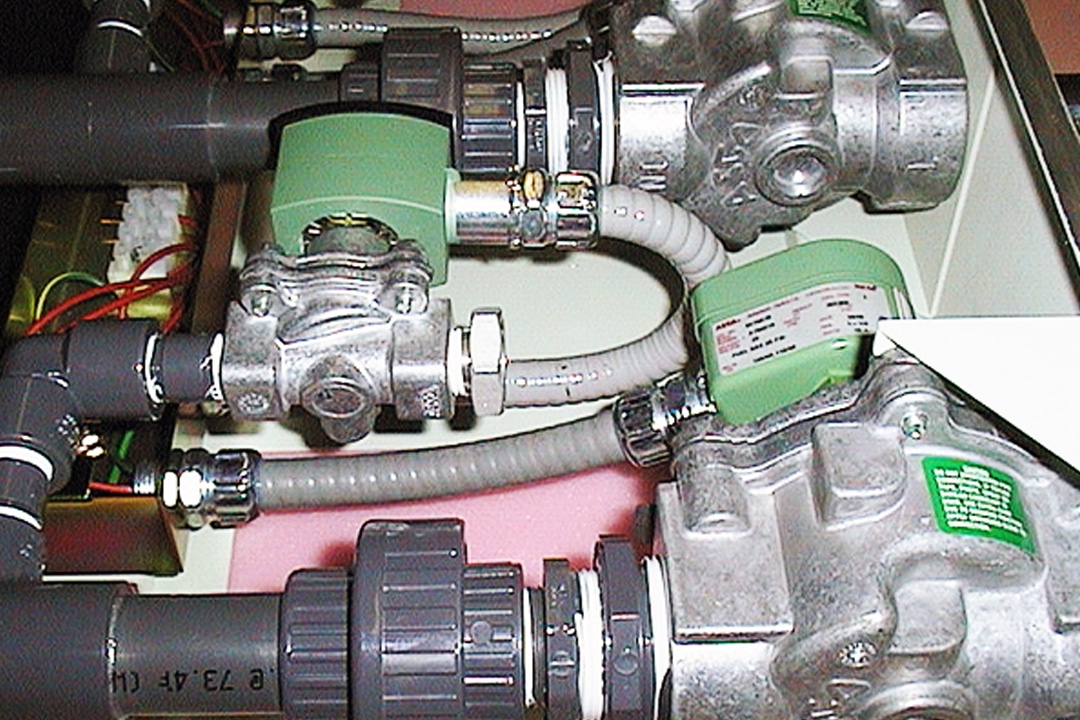

Complex, highly engineered capital equipment that contain elements of motion control and/or process automation often includes assemblies that contain both mechanical and electrical elements.

If your electro-mechanical assembly requirements include specialized skillsets such as the sourcing of custom sheet metal and precision machined parts, appropriate cable and wire management, precision alignment assembly techniques and validation and development of customized test fixtures and functional test procedures, then Federal Electronics is your logical choice.

Federal Electronics Partnership Benefits

US-Mexico Footprint Provides Access to Low-Cost Region Pricing

Includes Manufacturing of Labor-Intensive Assemblies & Sourcing of Custom Fabricated Metal

Federal Electronics hybrid US/Mexico manufacturing model, with facilities in Rhode Island and Sonora, Mexico, is custom configurable to address your unique requirements, as each site is fully capable of working either independently or in combination to deliver an optimal solution that delivers product where and when you need it with consistent quality and at a reduced cost.

Each facility is supported by a localized network of custom fabricated sheet metal and machined part supplier partners who have been qualified to our rigorous standards.

Our Mexico facility offers a significant cost advantage for labor intensive electro-mechanical assemblies and for labor intensive subassemblies that are destined for integration into a higher-level assembly at our Cranston, RI site.

Engineering Support For DFx

Test Procedures Developed for Motors, Encoders and Sensors

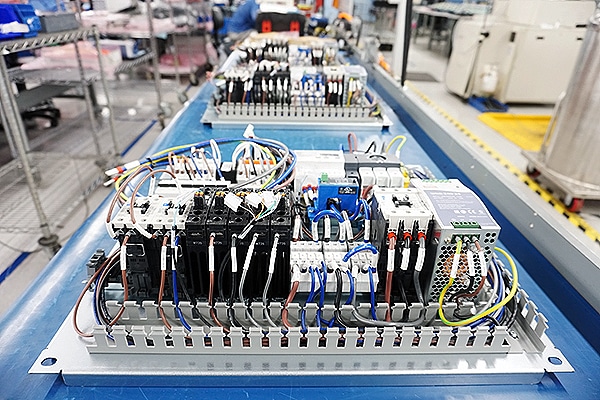

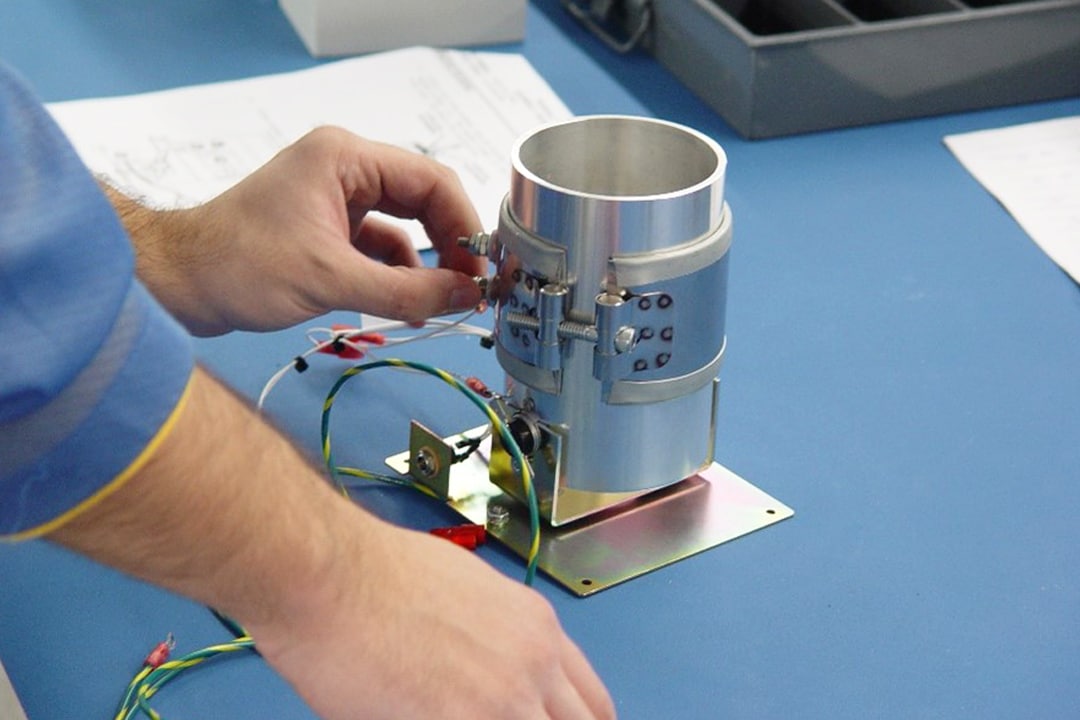

Following a thorough review of your documentation, manufacturing engineering will establish manufacturing processes that typically include the creation of mechanical fixtures to ensure proper assembly orientation and alignment, especially for products that include multi-axis movement.

These processes can accommodate specialized requirements, such as the need for ESD protective measures for electronic components, or assembly/packaging within our Class 10,000 clean room. Our sourcing team will engage with supplier-partners specializing in various forms of custom fabricated, build-to-print, precision machined, sheet metal, and custom molded products. As these assemblies often include active components such as motors, encoders and/or sensors, our test engineering group will create a customized fixture and test procedure that validates your product to its functional specifications.

Custom Kanban Programs for JIT Delivery Improves Inventory Management

Dedicated Program Managers Ensure Adherence to Forecast

Electro-mechanical assemblies are great candidates for customized, 2-bin Kanban programs. Dedicated Program Managers at both plants enable Federal Electronics to administrate Kanban programs that maximize your inventory turns and delivers product as Just-In-Time requirements.

Maintaining stock levels for Federal-manufactured subassemblies (cable assemblies, wire harnesses, mechanical assemblies, etc.) aligned to finished product bin sizes increases throughput, ensures compliance with forecast requirements, and provides upside for drop-in, unplanned demand.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.