Cable and Wire Harness Assembly

Build-To-Print Cable and Wire Harness Assembly for Complex Products

US-Mexico Manufacturing Sites Deliver Cost-Effective Solutions for Cable and Wire Harness Assembly

If you are in need of a UL listed supplier partner with manufacturing facilities in both the US and Mexico for higher mix, lower volume build-to-print cable and wire harness assembly, then Federal Electronics is your best choice.

Since its inception, Federal Electronics has been a supplier of cable and wire harness assembly services to OEMs of high complexity, highly engineered and highly regulated capital equipment. While the vast majority of EMS facilities are geared towards lower mix, higher volume, lower complexity products, Federal Electronics has established a responsive, flexible and cost-effective solution for customers in challenging markets such as military and defense, industrial capital equipment, and medical.

Federal Electronics Partnership Benefits

UL Listing & IPC Certified Training Program

Consistent Quality Through Process Optimization & Extensive Training

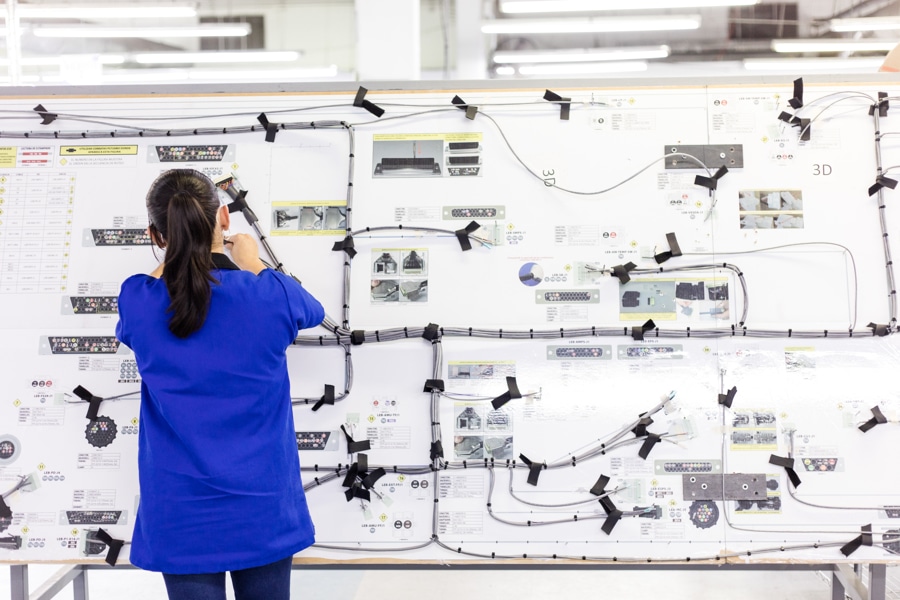

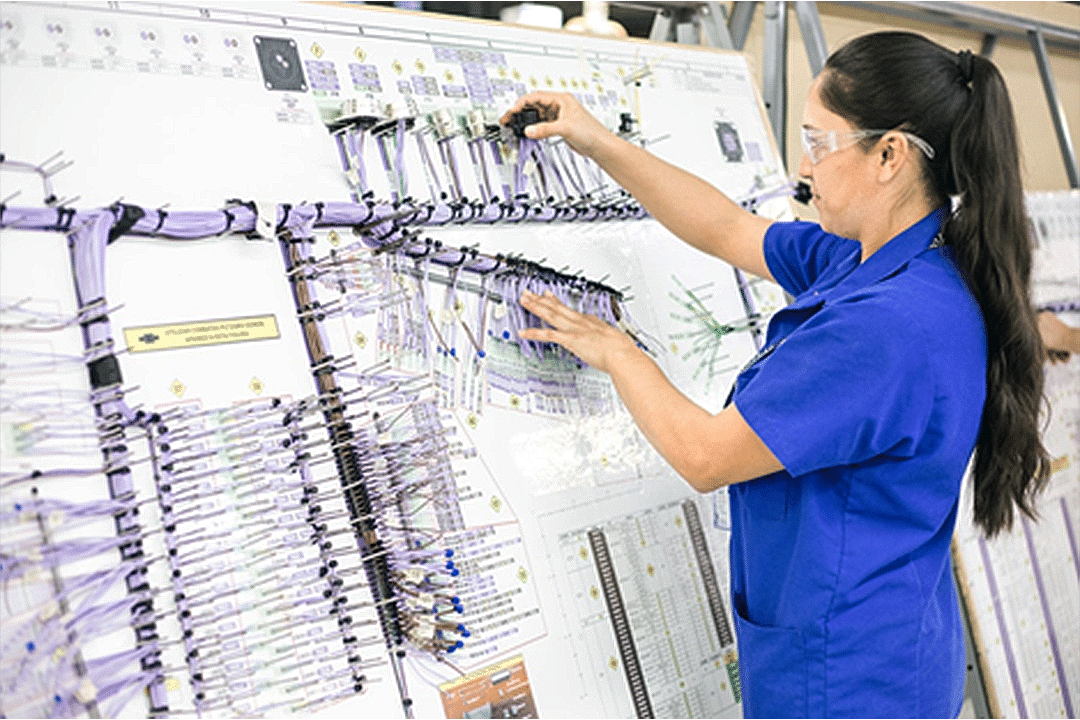

Due to higher labor content than other types of electrical and electronic products, wire harness assembly and cable assemblies are often prone to workmanship issues. To minimize opportunities for error, Federal Electronics’ manufacturing engineers have selectively modified and implemented automated processes to work more effectively in an environment of higher mix, lower volume requirements typically associated with highly complex capital equipment.

In addition, Federal Electronics operators in Hermosillo are trained to IPC-A-620 Class 3, and operators in the Cranston facility are trained to IPC-A-620 Class 3 and J-Std-001 Class 3 by IPC Certified trainers.

US-Mexico Manufacturing Footprint

Our Hybrid Model Blends the Best of Both Facilities

Federal Electronics’ hybrid US-Mexico production model provides options for every customer based on their unique priorities. Our Cranston, RI facility is the manufacturing destination of choice for customers within the military and defense industries and those bound by the Build America Buy America Act.

Our Hermosillo, Sonora, Mexico facility serves customers who prioritize cost reductions and are not bound by industry or governmental regulations and is particularly valuable to customers in the Western half of the United States when transit and logistics benefits are considered.

Labor-intensive cable assemblies and wire harnesses can be produced in our Mexico facility and shipped to Cranston for integration into large capital equipment, providing additional cost-reduction benefits for many customers.

Engineering Resources to Optimize Processes & Reduce Labor Content

Automated Processes Applied to Lower Volumes Delivers Lower Costs & Higher Yields

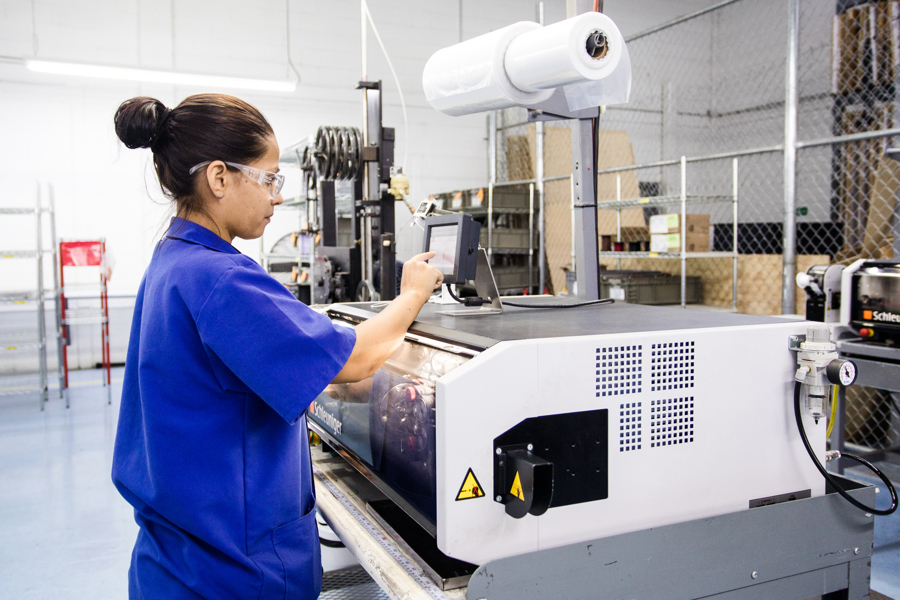

Cost savings associated with Mexican production is significant. Federal Electronics has invested heavily in equipment that automates prep processes such as wire marking, de-reeling, cutting, stripping, and crimping for cable assemblies and wire harnesses. Federal Electronics’ manufacturing engineers have modified high-volume methods, such as the use of automated carousels, to work effectively in lower volume, higher mix, higher complexity programs. These process improvements yield lower labor costs, higher throughput, and higher yields.

Our Hermosillo facility also generates cost reductions by supplying labor-intensive sub-assemblies to the Cranston site for integration into higher-level assemblies, such as electronic controllers, industrial control panels, and frame-level systems integration.

Finished Product Stocking Through Custom Kanban Programs

Production Capacity Flexes Within 24 Hours of Your Demand Signal

OEMs of complex systems and capital equipment often have project profiles that consist of multiple cable assembly and wire harness part numbers that include diverse interconnect technologies, are produced in lower volumes, and delivered in complete sets. These situations are ideal for limited liability agreements, driven by forecasted demand and replenished through 2-bin Kanban programs.

To support these requirements, operations at both sites are synchronized in a centralized IT system. ERP modules for Material Requirements Planning (MRP) and Scheduling run every night, ensuring that material allocations and production schedules are aligned with customer priorities, allowing us to flex capacity in response to fluctuations in demand. Where Kanban systems are deployed, bin sizes are reviewed and adjusted on a quarterly basis (at a minimum).

Federal Electronics has developed a suite of standard solutions that blend administrative, engineering, and manufacturing models that ensure repeatable and reliable performance while delivering lower costs and consistent quality.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.