Integrated Electronic Manufacturing Solutions

Electronic Manufacturing Services Tailored for Your High Complexity Projects

Vertical Integration and US-Mexico Footprint Delivers Cost-Effective Integrated Electronic Manufacturing Solutions

If you are an OEM of complex, highly engineered capital equipment looking for a supplier to manage your higher-level electronics assembly but don’t have the volume or spend to interest the Tier 1 contract manufacturers, then Federal Electronics is your logical choice.

Federal Electronics has developed a unique suite of capabilities that mirror those of Tier 1 CMs but are tailored specifically for higher mix, lower volume, high complexity products often found in the Defense, Industrial and Medical markets.

Federal Electronics Partnership Benefits

Full Program Support from NPI Through Scaled Production

Vertical Integration Increases Influence Over Supply Chain and Manufacturing

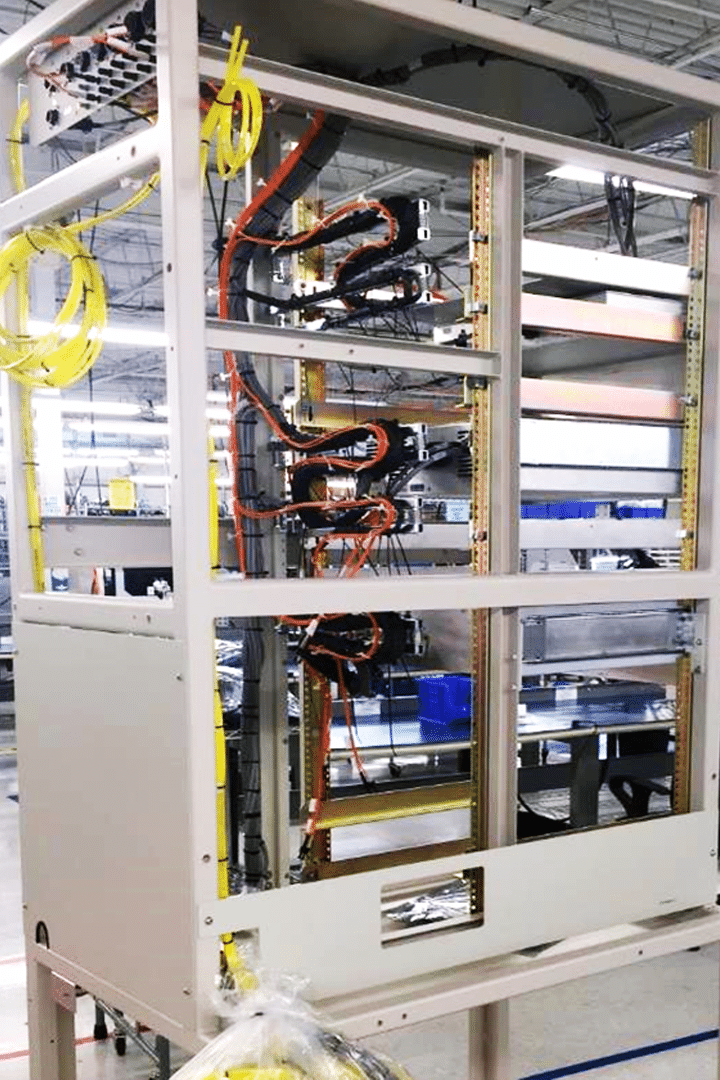

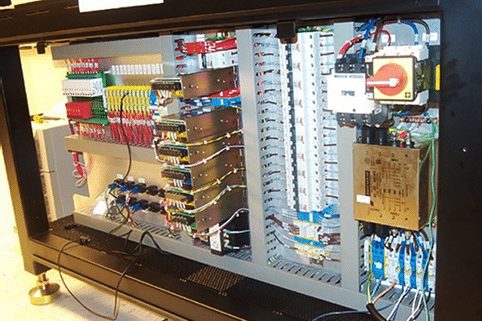

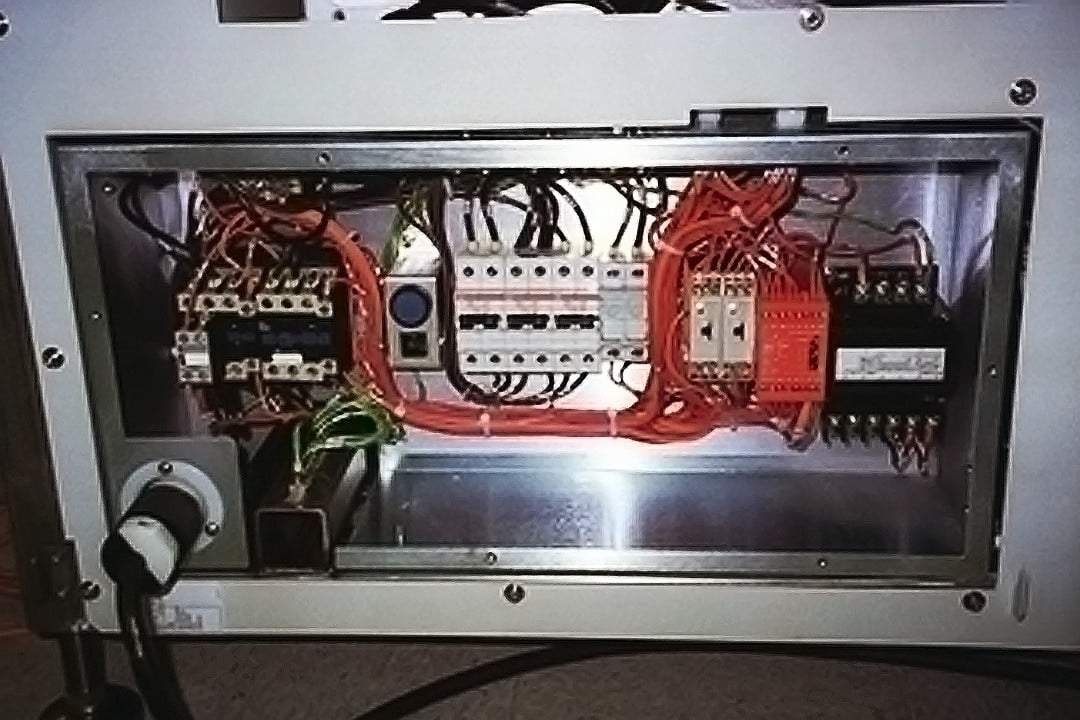

Integrated Electronic Manufacturing, or Higher-Level Assemblies (HLAs), pose significant administrative challenges due to multi-level BOMs, mix of electronics manufacturing technologies, and complicated supply chains. Federal Electronics vertical integration model, which includes PCBA manufacturing, cable assemblies and wire harness assemblies, combined with our US-Mexico manufacturing sites, increases our influence over both the supply chain and a higher percentage of the manufacturing process.

At the inception of your program, technical NPI Program Managers from each facility (if applicable) are assigned to your project. Acting as your internal advocates, they will coordinate all internal activity, communicating project status on a weekly basis, ensuring your program stays on schedule, within budget, and meets the specified requirements. With product configuration, manufacturing/test processes, and supply chain established, the program is transferred to Sustaining Program Managers to administer the ramp to production volumes.

US-Mexico Manufacturing Footprint

The Best of Both Facilities for Optimized Integrated Electronic Manufacturing Solutions

Higher-Level Assemblies typically consist of multiple integrated electronic manufacturing process types, including cable assemblies, wire harness assemblies, box build assembly, electromechanical assemblies, and/or industrial control panels.

Federal Electronics’ hybrid US/Mexico model provides attractive options for every customer based upon their priorities. Our Cranston, RI facility is the manufacturing destination of choice for customers within the military and defense industries and those bound by the Build America Buy America Act.

Our Hermosillo, Sonora Mexico facility serves customers who prioritize cost reductions and are not bound by industry or governmental regulations and is especially valuable to customers in the Western half of the United States due to transit and logistics benefits.

By selectively sourcing higher labor subassemblies at our Mexico facility, Federal Electronics delivers lower costs while mitigating the risks associated with overseas production.

Centralized IT System Links US-Mexico Facilities

Fully Integrated ERP Provides Complete Project Visibility

Federal Electronics centralized IT system integrates program management, engineering, supply chain, manufacturing, and quality resources across our US and Mexico facilities, ensuring transparent communication throughout the development and scaled production processes.

With critical business processes integrated by our ERP system, our two facilities work in tandem to manage complex higher-level assemblies that consist of multi-level BOMs and multiple electronics manufacturing process types, such as PCBAs, cable assemblies, wire harnesses and electronic assemblies. Nightly MRP and finite scheduling modules provide an accurate assessment of project status as changes in supply and demand are captured within 24 hours of entry.

Vertical Integration Reduces Cost and Increases Responsiveness

Nightly MRP and Resource Scheduling Improves Delivery Performance

Federal Electronics’ vertical integration model is a critical driver for our integrated electronics manufacturing solution. By offering printed circuit board assembly, cable assembly, wire harnesses, electronic assemblies and industrial control panels, we control a higher percentage of both the total supply chain and the manufacturing process overall. This approach eliminates non-value add margin stack-up associated with other less vertically integrated electronics manufacturing companies while increasing our leverage and purchasing power with our supplier-partner network.

Our MRP and Scheduling modules run on a nightly basis, providing Program Management with a fresh and accurate assessment of project status, including real-time tracking of raw material, WIP and finished goods inventory to minimize shortages and overstock situations.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.