7 Critical Factors in Selecting an Electronics Contract Manufacturer

Not all EMS providers are created equal, and knowing the right selection criteria to consider can make the difference between success and costly mistakes. Choosing the right electronics manufacturing service (EMS) provider is one of the most important decisions an OEM can make. An electronics contract manufacturer does not just build your assemblies — they become an extension of your supply chain, quality systems, and reputation in the market.

The wrong choice risks cost overruns, delays, and dissatisfied customers. The right choice builds resilience, scalability, and competitive advantage. To get there, OEMs need a clear supplier selection process backed by the right evaluation criteria.

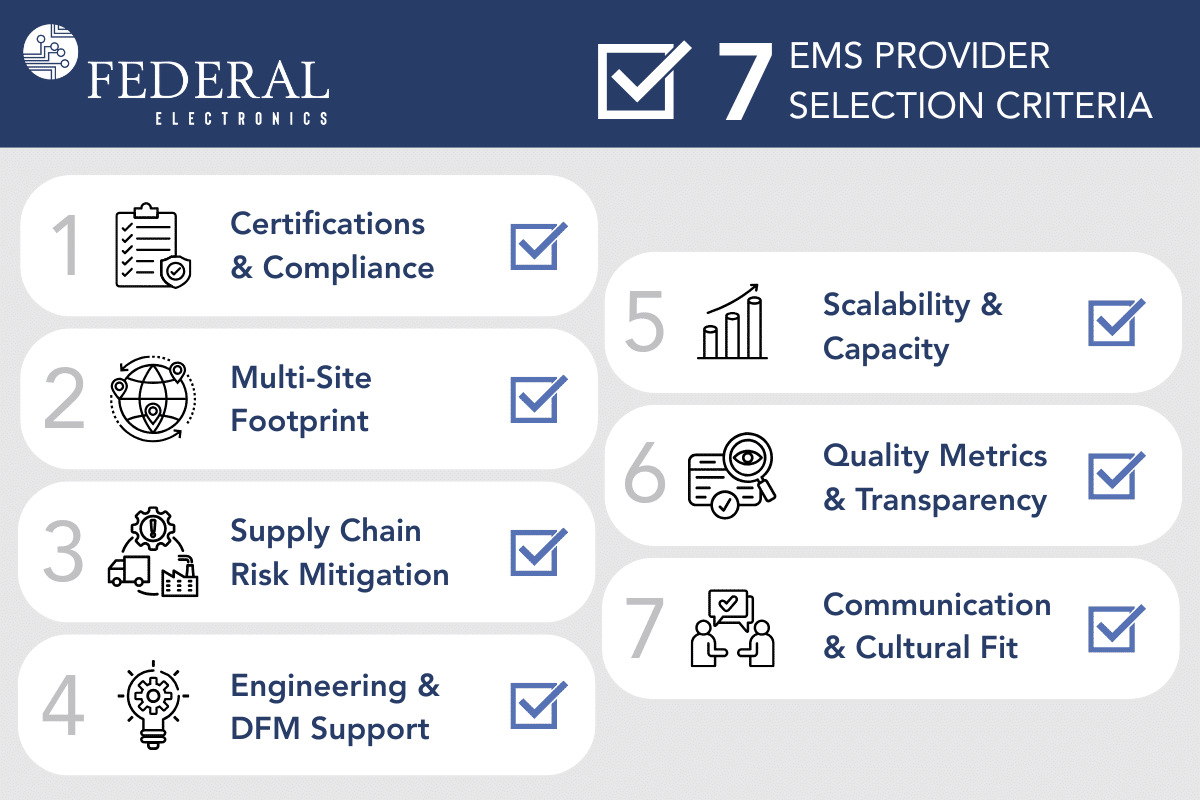

This guide walks through the top 7 supplier selection criteria to consider before committing to a partnership.

Supplier Selection Process: Why It Matters

The supplier selection process is more than just comparing quotes. Procurement and supply chain leaders must weigh factors like compliance, scalability, risk management, and cultural fit. Without a structured approach, OEMs risk:

- Production disruption due to weak supply chain planning.

- Higher total costs from hidden inefficiencies and poor communication.

- Field quality issues that damage reputation long after shipment.

- Customer churn from missed schedules or inconsistent performance.

A thorough evaluation process, grounded in the right questions, helps ensure that your chosen electronics contract manufacturer is capable, reliable, and aligned with your goals.

Top 7 Supplier Selection Criteria for OEMs

When evaluating EMS providers, focus on these seven critical criteria:

- Certifications & Compliance

Highly regulated industries often require specific certifications or registrations to demonstrate alignment with industry requirements. Consideration includes:- Quality Management Systems (QMS): One way to establish proper alignment with a supplier is to confirm certification to the appropriate QMS standard. While ISO 9001 serves as the baseline, both AS9100 and ISO 13485 add sector-specific requirements for the aerospace/defense and medical industries respectively.

- Workmanship: With few exceptions, most OEMs will reference an industry-wide workmanship standard within their product specifications. Selecting suppliers whose operations are compliant with commonly accepted standards such as IPC-A-610 for printed circuit assemblies, IPC/WHMA-A-620 for cable assemblies and wire harnesses, and J-STD-001 for Soldered Electrical and Electronic Assemblies increases the likelihood that quality performance expectations will be met. For most high-reliability OEMs, confirmation of compliance to Class 3 for each standard provides further confidence in the selection.

- Other: For military/defense applications, ITAR registration with the State Department is critical. Defense Department insistence on compliance with cybersecurity standards such as NIST 800-171 and CMMC Level 2 ensures the supplier can handle government IP, which also translates well to non-defense customers who have become equally interested in security controls that protect their information and minimizes the potential for a successful cyber-attack. FDA registration provides further assurances for medical applications while compliance with the Responsible Business Alliance (RBA) standards promotes responsible business conduct in global supply chains.

- Multi-Site Footprint

Multi-site footprints offer several advantages, especially as part of a cohesive business continuity strategy or to provide sourcing flexibility. If one of the sites is located nearshore in a lower cost region, cost optimization beyond domestic production becomes an additional benefit, both in terms of custom fabricated part sourcing and a labor perspective. - Supply Chain Risk Mitigation

Due to a highly globalized supply chain that is sensitive to disruptions, risk mitigation is a critical requirement when selecting an electronics manufacturing service provider. Look for expertise in multi/dual-sourcing, the use of strategic stockpiles and bonded inventory, and the ability to conduct BOM risk analysis and utilize real-time monitoring platforms such as Z2Data, SiliconExpert, and Supplyframe to track shortages, End-Of-Life notices, and climate/geopolitical events. - Engineering & DFM Support

EMS providers who take on electronic manufacturing projects should have a strong engineering front-end to support new programs as well as sustaining, legacy production. Look for evidence of early engagement in New Product Development where design reviews include DFx inputs before design freeze, the ability to support quick-turn prototyping with immediate feedback on product improvements to the design team, and a separate sustaining manufacturing engineering team with expertise in the appropriate resources (PCBA, cable assembly and wire harness, box build, etc.) to provide support throughout the product lifecycle while offering continual improvement in terms of yield, cycle time, and cost. - Scalability & Capacity

Whether ramping a new product to production levels or adjusting to demand volatility for legacy product, the EMS provider must have the ability to quickly and effectively align material and labor capacity with customer product demand. Understanding a suppliers MRP cadence (once per week may be insufficient), scheduling methodology (finite-scheduling algorithms provide the most accurate results), and Throughput reporting that identifies misalignment between customer order expectations and workorder completion dates can ensure appropriate product supply over the long term. - Quality Metrics & Transparency

Aligning with an electronics manufacturing partner with the proper Quality Management System goes a long way towards meeting industry-specific expectations, and include AS9100 (Aerospace/Defense), ISO 9001 (High-reliability Industrial), and ISO 13485 (Medical). Additional requirements in the Hi-Rel market space include traceability to the component level, advanced and automated inspection capabilities (Automated Optical Inspection, 3D Solder Past Inspection, etc.), and front-end design-integrated quality that may include FMEA for early risk analysis at the product/process introduction stage. - Communication & Cultural Fit

Communication and cultural fit can make or break an OEM – EMS provider relationship, even when all the criteria measured with objective evidence is favorable. Truly successful relationships with electronics manufacturers are based on strategic alignment, not on transactions. Shared values (quality, integrity, urgency, etc.) and a mutual commitment to a win-win outcome are foundational when it comes to meeting expectations for the long term.

Why Federal Electronics

At Federal Electronics, we combine the general advantages of EMS providers with unique differentiators that set us apart. While many EMS providers claim to deliver quality and efficiency, few combine the depth of supply chain expertise, dual-site mirrored operations, and compliance certifications that Federal Electronics provides.

With operations in the U.S. and Mexico, robust AS9100/ISO quality management systems, and decades of experience in high-reliability industries such as aerospace, medical, industrial, and semiconductor equipment, Federal helps OEMs de-risk their supply chain and scale with confidence.

If you are evaluating an electronics contract manufacturer, Federal Electronics offers the strategic partnership, engineering support, and supply chain resilience that OEMs need to compete in today’s environment.

Conclusion

The electronics manufacturing supplier selection process can feel complex, but choosing the right EMS provider who is best suited for your needs out of the gate is worth the effort. By focusing on compliance, flexibility, risk mitigation, engineering support, scalability, transparency, and cultural fit, OEMs can choose electronics contract manufacturers that protect their supply chain and strengthen their market position.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.