What Are the Critical Elements of a Successful NPI Program?

- 1. Clear Understanding of What NPI Means in Electronics Manufacturing

- 2. Design for Manufacturability (DFM) and Design Collaboration

- 3. Prototyping and Functional Validation

- 4. Supply Chain and Material Readiness

- 5. Process Engineering and Validation

- 6. Cross-Functional Communication and Program Management

- 7. First Article & Release for Production

- 8. Continuous Improvement and Post-Launch Support

- Conclusion: Building Confidence Through a Disciplined NPI Approach

- Partner with Federal Electronics

Launching a new electronic product is a complex process that requires more than a great design—it demands a disciplined, well-structured New Product Introduction (NPI) program. For Original Equipment Manufacturers (OEMs), a successful NPI process bridges the gap between product development and full-scale electronics manufacturing, ensuring a smooth transition from prototype to production.

When executed effectively, NPI reduces risk, accelerates time-to-market, and safeguards quality across every stage—from initial design reviews to pilot builds and production ramp-up. For OEM engineering and supply chain leaders evaluating Electronics Manufacturing Services (EMS) partners, understanding what makes an NPI program effective is key to selecting the right collaborator.

Below, we explore the critical elements of a successful NPI program, grounded in the realities of PCBA, box-build assembly, and cable and wire-harness assembly.

1. Clear Understanding of What NPI Means in Electronics Manufacturing

So, what is NPI, and why does it matter? In electronics manufacturing, NPI—or New Product Introduction—is a structured, cross-functional process that brings a new design from concept to production readiness.

While definitions vary across industries, in EMS, NPI focuses on verifying that a product’s design, materials, and assembly methods are optimized for manufacturability, testability, cost, and long-term reliability. It forms the foundation of any OEM-EMS partnership and typically includes:

- Design evaluation and feedback — Design for Manufacturability (DFM) and Design for Test (DFT)

- Material sourcing and supply-chain readiness

- Process validation through pilot and pre-production builds

- Transfer to full-scale production

When OEMs treat NPI not as a checklist but as a disciplined, data-driven process, they reduce costly redesigns and late-stage surprises.

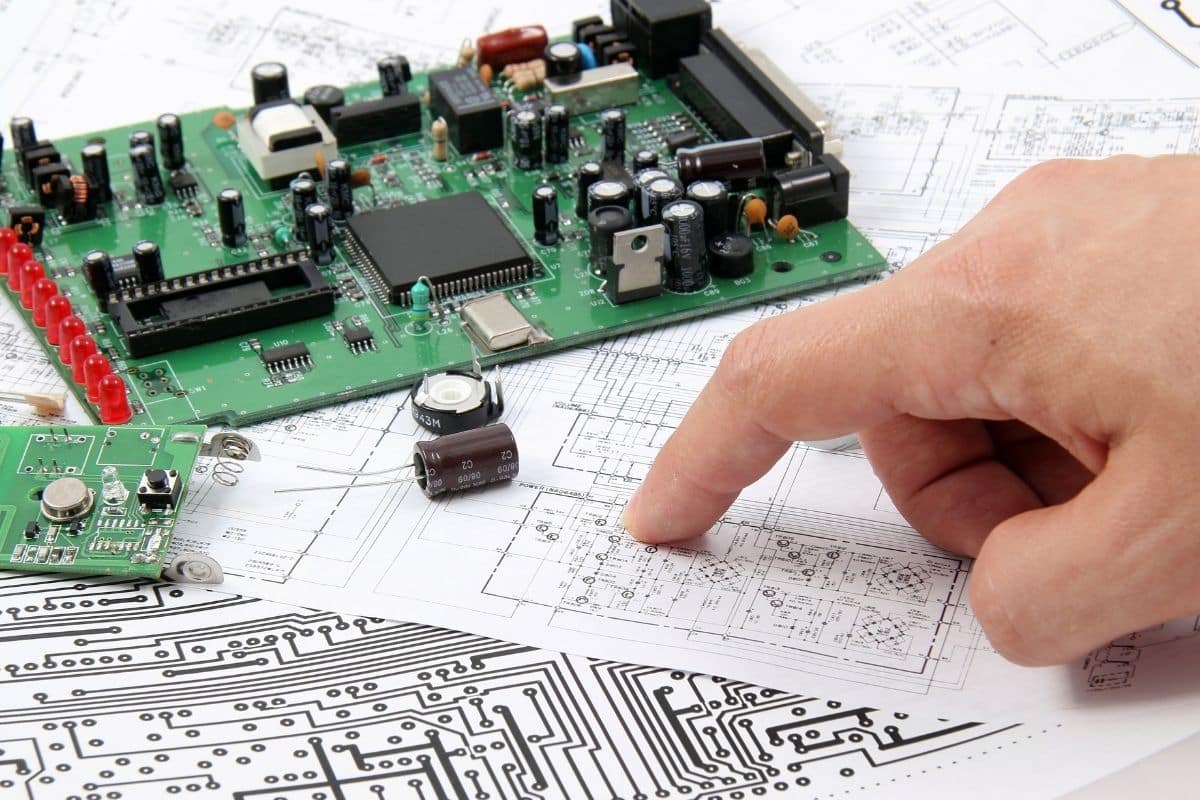

2. Design for Manufacturability (DFM) and Design Collaboration

A successful NPI program begins early—during product development—with a proactive Design for Manufacturability (DFM) approach. DFM reviews uncover issues that could hinder production efficiency or product reliability long before the first PCBA, cable assembly, or wire harness is built.

In an EMS environment, DFM often includes:

- PCB layout reviews to ensure trace spacing, component placement, and thermal management meet manufacturing constraints.

- Material and component availability checks to prevent sourcing delays.

- Tolerance analysis for mechanical fit in box builds and subassemblies.

- Assembly and rework accessibility reviews for wire harnesses and cable assemblies.

A collaborative design phase—where OEM engineers and EMS manufacturing experts exchange insight—ensures that every design is buildable, testable, and scalable from the start.

3. Prototyping and Functional Validation

Prototyping is more than proof of concept—it’s where the product’s design and functionality are validated before entering process engineering. During this phase, EMS providers build and test early units to confirm fit, form, and function, ensuring that electrical, mechanical, and cosmetic requirements align with design intent.

In electronics manufacturing, this stage typically includes:

- PCBA builds to validate soldering profiles, reflow quality, and component placement.

- Box-build assemblies to confirm mechanical integration and cable routing.

- Box-build assemblies to confirm mechanical integration and cable routing.

- Wire-harness and cable-assembly testing to ensure electrical continuity and proper fit within enclosures.

Each prototype provides critical feedback for both engineering and operations teams, driving refinements that strengthen design reliability and manufacturability before the product moves into formal process validation.

4. Supply Chain and Material Readiness

Even the most innovative design will stall without a robust supply chain. A strong NPI program integrates supply-chain readiness from the beginning, aligning procurement, materials planning, and vendor qualification with the product’s lifecycle needs.

Key supply-chain-related NPI activities include:

- Approved Vendor List (AVL) verification and identification of alternate components for risk mitigation.

- Long-lead-time forecasting to prevent schedule delays.

- Material traceability setup for regulatory or customer requirements.

- BOM validation to catch discrepancies before they reach production.

An experienced EMS provider acts as an extension of the OEM’s sourcing team—balancing cost, lead time, and availability while managing relationships with global component suppliers.

5. Process Engineering and Validation

Once design and materials are finalized, process engineering ensures that every manufacturing step is documented, repeatable, and verifiable. In electronics assembly, this includes:

- Developing assembly documentation, work instructions, and process-flow diagrams.

- Programming and validating SMT lines, selective soldering, and conformal-coating processes.

- Establishing functional test procedures for PCBAs, subassemblies, and final box builds.

- Applying Statistical Process Control (SPC) and failure-mode analysis to confirm process stability.

Process validation during NPI minimizes defect risk as production scales and gives OEMs confidence in the EMS partner’s quality systems.

6. Cross-Functional Communication and Program Management

Every NPI effort succeeds or fails on communication. A truly effective program unites design, quality, supply-chain, and manufacturing teams under one cross-functional structure, guided by an experienced Program Manager.

Program management responsibilities during NPI include:

- Coordinating milestone reviews between OEM and EMS stakeholders.

- Tracking deliverables such as design files, ECOs, and process documentation.

- Maintaining transparency on schedule, cost, and technical risks.

- Facilitating design changes and ensuring alignment before ramp-up.

OEMs evaluating EMS partners should look for proven NPI governance frameworks that promote clarity, accountability, and adaptability throughout the launch.

7. First Article & Release for Production

The First Article process is a critical checkpoint in the transition from controlled builds to full-scale manufacturing. During a First Article build—also known as First Article Inspection (FAI)—the EMS provider performs a controlled initial run to verify that every material, component, and assembly operation meets engineering and quality requirements. Each result is documented and compared against the approved design, confirming that the process is stable, repeatable, and capable of consistent output.

For PCBA, box-build, and cable or wire-harness assemblies, the First Article serves as both a quality assurance measure and a process audit, giving OEM teams confidence that design intent translates into high-quality, production-ready outcomes.

Once the First Article is reviewed and approved, the program moves into the Release for Production phase. At this stage, the EMS provider finalizes documentation, validations, and readiness checks to ensure all process parameters, tooling, and materials meet release criteria for full-scale production.

During initial production runs, EMS teams continue to monitor yield, takt time, and assembly efficiency, feeding insights back to engineering and quality teams. This stage bridges the final gap between pilot activities and mass manufacturing—turning validated lessons into documented best practices for long-term production success.

8. Continuous Improvement and Post-Launch Support

A successful NPI program doesn’t end with the first shipment—it establishes a foundation for continuous improvement. Once production stabilizes, leading EMS providers analyze field data, warranty returns, and process metrics to enhance product quality and yield.

Post-launch NPI activities may include:

- Root-cause analysis and closed-loop corrective actions.

- Process optimization for greater throughput or reduced cost.

- Product-lifecycle management and incorporation of engineering changes.

By maintaining the same cross-functional mindset post-launch, OEMs and EMS providers create a feedback-rich partnership that sustains quality and competitiveness throughout the product’s life.

Conclusion: Building Confidence Through a Disciplined NPI Approach

A disciplined, collaborative NPI process is the hallmark of a mature EMS partner. For OEM engineering, supply-chain, and supply chain teams, evaluating an EMS provider’s NPI capabilities is one of the most reliable ways to gauge long-term partnership value.

When an NPI program incorporates DFM expertise, supply-chain control, process validation, First Article verification, and transparent communication, it transforms product launches from high-risk ventures into predictable, data-driven successes.

Whether the project involves PCB assembly, box-build integration, or cable and wire-harness assembly, the principles remain the same: design smart, validate early, communicate often, and never stop improving.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.