Case Study: Reducing Lead Times and Improving Inventory Turns Through a Forecasted Kanban System

Overview

A mid-sized industrial equipment OEM faced chronic supply chain instability caused by poor forecasting, erratic inventory levels, and unreliable material availability. Their demand patterns were highly unpredictable, and their planning environment lacked the structure necessary to keep inventory aligned with real consumption.

To resolve these issues, the OEM partnered with Federal Electronics, an Electronics Manufacturing Services (EMS) provider, to implement a forecasted Kanban system designed to stabilize inventory turnover, reduce lead times, and restore confidence in their production schedule.

The Challenge

The customer operated with no formal forecasting process. Forecasts were provided infrequently and were used only to estimate labor—not to drive material planning. Their ERP-generated purchase orders were based on outdated or inaccurate lead times, which caused significant planning breakdowns across their supply chain.

Key Pain Points

1. Erratic Inventory Turnover

The customer’s inventory levels swung dramatically due to:

- Inaccurate internal lead times

- Reactive, rather than proactive, purchase ordering

- Poor ordering policies

This resulted in cycles of overstocking followed by material starvation, with no consistent inventory turnover ratio.

2. Unreliable Lead Times

Assembly lead times in their system were “grossly lower” than actual availability.

This mismatch created constant shortages and schedule slips.

3. Volatile and Late Demand Changes

The OEM’s end customers frequently:

- Placed orders well within realistic lead time

- Changed product configurations late in the production cycle

These swings put continuous pressure on material availability and production readiness.

4. Material Shortages and Excess Stock

Due to the lack of structured planning:

- Shortages were common

- Excess inventory accumulated when the OEM attempted to “get ahead”

- Excess turned into stranded inventory when demand normalized

Primary Source of Pressure

Poor planning—specifically, the absence of a reliable forecast-driven material pipeline.

Why Kanban Was the Right Solution

The OEM realized that continuing with discrete purchase orders could not deliver:

- Material availability

- Price stability

- Predictable replenishment

- Higher supply chain visibility

A properly structured Kanban system, tailored to their environment, promised a steadier flow of material with inventory levels matched more closely to actual demand.

Kanban Was Chosen To:

- Replace reactive discrete PO ordering

- Build a forecast-driven material pipeline

- Provide clearer responsibility boundaries through a limited liability agreement

- Achieve price certainty and eliminate supplier surprises

- Respond more effectively to short-lead-time demand spikes

Implementation Approach

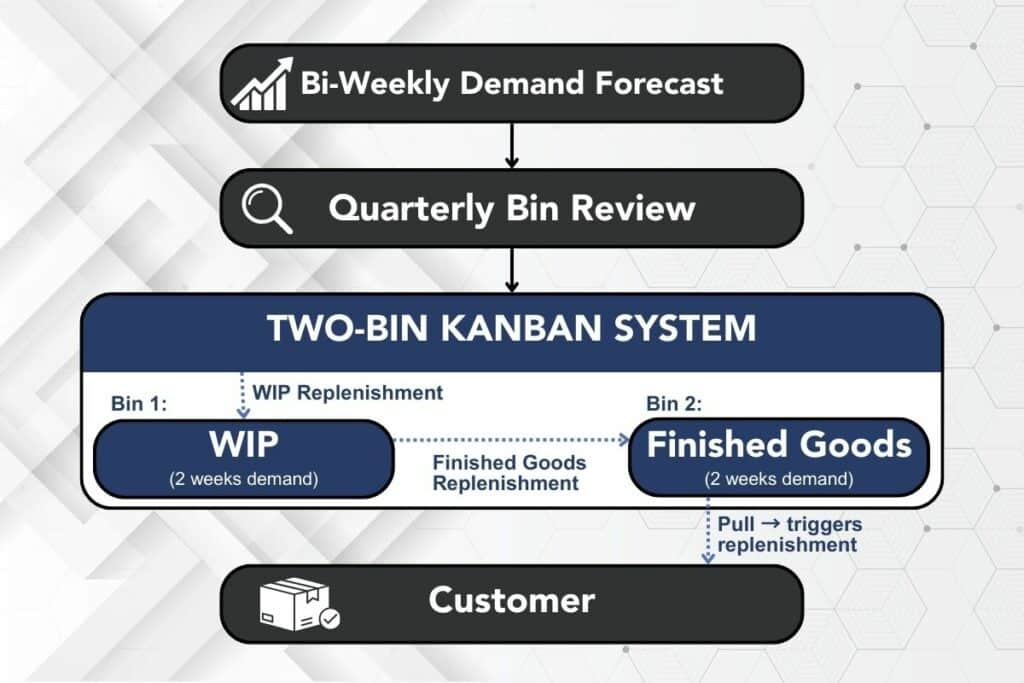

Federal Electronics deployed a two-bin Kanban system, supported by improved forecasting, supplier coordination, and structured inventory reviews across its PCBA and cable and wire harness assembly operations.

1. Two-Bin Structure

- Each bin represented approximately two weeks of demand.

- One bin was held in Finished Goods, the other in WIP.

2. Bin Size Methodology

Bin sizes were based on projected demand over the next 90–120 days, and:

- Reviewed quarterly

- Updated immediately when biweekly forecasts indicated significant deviation

Formalize your BOM management process—regularly reviewing approved alternates and end-of-life components ensures your product roadmap isn’t derailed by availability issues.

3. Forecast Integration

The customer provided forecasts every two weeks, enabling proactive adjustments instead of reactive scrambling.

4. VMI Consideration

A VMI model (min/max replenishment) was discussed but ultimately not selected.

The customer opted to implement a classical Kanban model for clarity and alignment with their operational structure.

Results

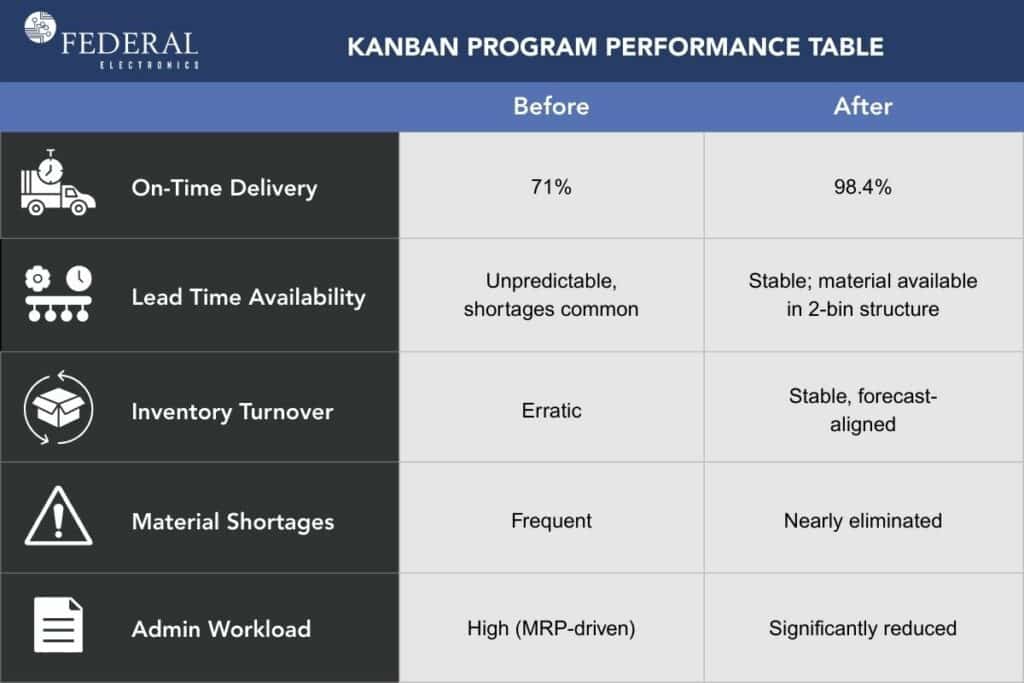

The Kanban implementation delivered significant and measurable improvements across supply chain stability, inventory behavior, and production performance.

1. Lead Time Reduction

Once the material pipeline stabilized:

- Material shortages virtually disappeared

- Federal could maintain predictable bin stock

- Finished goods availability aligned reliably with the OEM’s production schedule

The OEM could now build to schedule rather than chase shortages.

2. More Stable Inventory Turnover

Through structured bin reviews and proactive forecast monitoring:

- Inventory stayed within appropriate limits

- Excess stock was minimized

- Response capability to short-term demand spikes improved significantly

Inventory turnover shifted from erratic to consistent and healthy.

3. Elimination of Shortages and Line Stoppages

The customer’s chronic shortage issues were essentially eliminated—a direct result of:

- Accurate forecast-driven replenishment

- Realistic lead times

- Structured inventory staging

4. Reduced Administrative Burden

Kanban eliminated the need for:

- Dozens of discrete purchase orders

- Constant PO line changes

- Multiple MRP-driven updates

Administrative responsibility moved largely to the supplier side, freeing internal resources.

5. Increased Supply Chain Visibility

With shared forecasts and supplier collaboration, the customer gained:

- Insight into long-term material commitments

- Earlier detection of at-risk components (obsolescence, geopolitical risk, environmental events)

- Better planning alignment with Federal and critical suppliers

This visibility enabled proactive mitigation rather than reactive fire-fighting.

6. Measurable Service Improvement

On-time delivery for Kanban assemblies improved from 71% to 98.4%. This reliability was one of the most notable outcomes of the Kanban system.

Conclusion

Through a carefully designed and forecast-driven Kanban system integrated with its Electronics Manufacturing Services (EMS) capabilities, Federal Electronics transformed an unstable, reactive procurement environment into a predictable, efficient, and scalable material pipeline.

The result was a dramatic improvement in:

- Lead time performance

- Inventory turnover stability

- Supply chain visibility

- Production continuity

- Administrative efficiency

This case demonstrates how Kanban, when implemented with accurate forecasting and supplier alignment, is one of the most effective tools for stabilizing complex, demand-variable electronics manufacturing environments.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.