Unlocking 8 Operational and Financial Benefits with a 2-Bin Kanban System

- Why Monthly Forecasts + Kanban Work Better Than Purchase Orders

- 1. Inventory and Working Capital Benefits

- 2. Improved Service Levels and Responsiveness

- 3. Forecast Visibility Without Forecast Liability

- 4. Fewer Expedites, Less Firefighting

- 5. Better CM Capacity and Pricing for the OEM

- 6. Clear Accountability Between OEM and EMS Partner

- 7. Reduced Excess, Obsolete, and Stranded Inventory

- 8. Improved Trust and Data Quality Over Time

- How the Model Works in Practice

- Bottom Line for OEMs

- Partner with Federal Electronics

An OEM can unlock significant operational, financial, and service-level benefits by combining monthly rolling forecasts with a 2-bin Kanban replenishment system at thier electronics manufacturing service (EMS) provider or electronics contract manufacturing partner. The real power comes from separating planning from execution—forecasting sets intent, while Kanban governs day-to-day flow.

This approach is especially valuable in high-reliability industries such as medical equipment manufacturing and defense electronics, but for different reasons. Medical OEMs typically operate in a continuous flow manufacturing environment due to constant demand, where strict availability, configuration control, and regulatory traceability are critical. Defense prime contractors, by contrast, manage event-driven, program-based demand that comes and goes, yet still contains pockets of repeatable manufacturing across long product lifecycles.

A forecast-supported 2-bin Kanban system allows both environments to communicate long-term program and demand intent while ensuring that actual production and replenishment remain governed by validated consumption rather than speculative forecasts.

For medical equipment manufacturers, a forecast-supported Kanban system supports high service levels and predictable replenishment while tightly limiting inventory exposure to qualified, compliant material only. By separating demand planning from execution, medical OEMs reduce shortages, minimize excess and obsolete inventory tied to design or regulatory changes, and improve readiness without compromising validation or change-control discipline.

For defense prime contractors, production must balance mission readiness, contractual obligations, and long-term sustainment across programs characterized by irregular demand, constrained and qualified supplier bases, and extended lifecycle requirements. A forecast-supported 2-bin Kanban system allows primes to communicate program and funding intent to their electronics manufacturing partners while ensuring that actual builds are driven by verified consumption. This improves material availability, reduces expediting and stranded-inventory risk, and supports disciplined, auditable execution across both high-volume consumables (such as missiles) and lower-volume, high-complexity platforms including radar, communications, and launch systems.

Below is a structured breakdown of the 8 benefits, followed by a simple operating model.

Why Monthly Forecasts + Kanban Work Better Than Purchase Orders

Traditional OEM-to-CM relationships rely on discrete POs and MRP signals. That system pushes demand downstream — often based on inaccurate lead times and volatile forecasts.

In contrast, monthly forecasts + Kanban separate planning from execution:

- Forecasts provide intent and visibility

- Kanban governs what actually gets built

This is a critical shift for electronics contract manufacturers supporting OEMs in high-mix, dynamic demand environments.

1. Inventory and Working Capital Benefits

Monthly forecasts allow an EMS partner to:

- Pre-position long-lead components

- Level-load capacity across EMS products like PCBA, cable and wire harness assembly, electromechanical assembly and box build assembly.

- Negotiate pricing and availability upstream

The Kanban system then caps inventory to only what is justified by consumption.

What OEMs see

- 15–35% reduction in total inventory is common

- Less cash tied up in excess and safety stock

- Lower risk of excess and obsolete material

For OEMs sourcing through electronics manufacturing service providers, this directly improves balance-sheet efficiency.

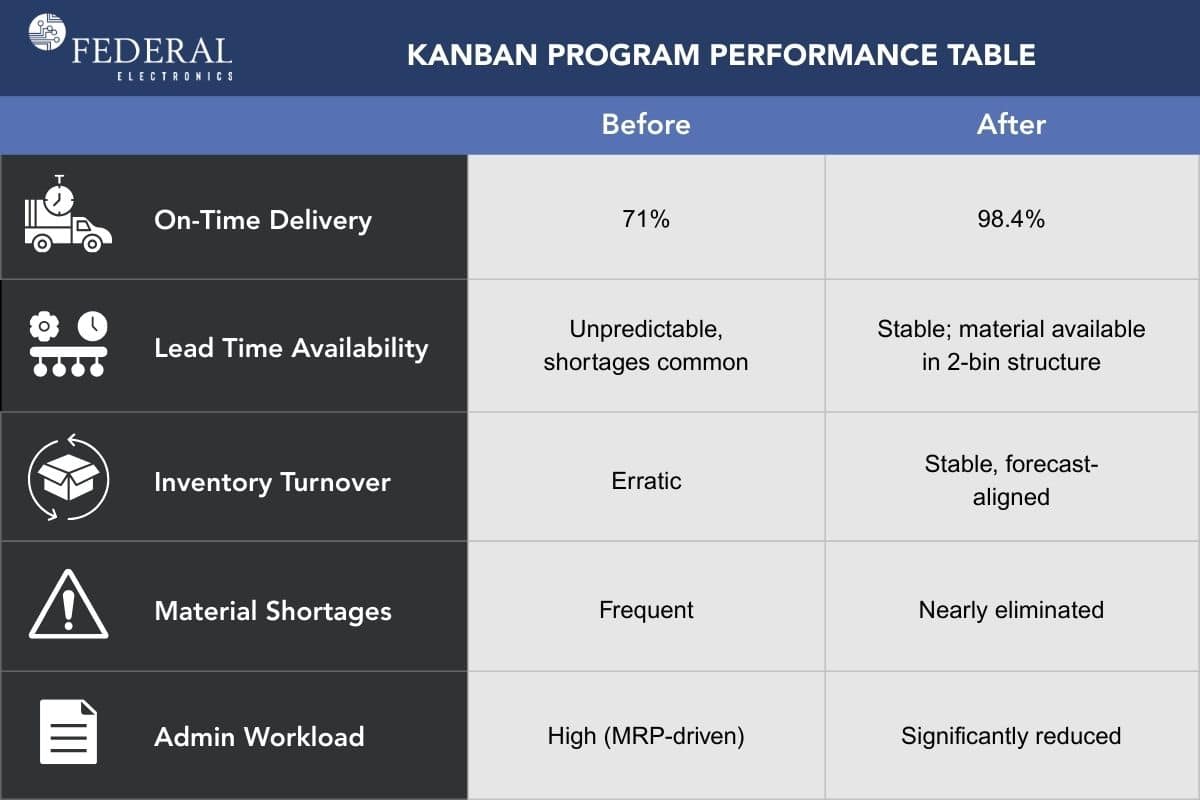

2. Improved Service Levels and Responsiveness

Kanban replenishment is triggered by actual consumption, not forecast noise.

The second bin acts as a time buffer, not an inventory hedge — giving the CM time to replenish without starving production.

What OEMs see

- Higher OTIF (on-time-in-full) performance

- Faster recovery from demand spikes

- Fewer line stoppages at the OEM

This is especially powerful in electronics production environments where even one missing component can halt shipment.

3. Forecast Visibility Without Forecast Liability

Monthly rolling forecasts allow an EMS partner to:

- Reserve capacity

- Secure long-lead materials

- Plan suppliers upstream

But:

- Forecast ≠ firm order

- Kanban controls execution

What OEMs see

- No forced builds due to forecast error

- Lower contractual risk

- Better planning without financial exposure

This is one of the most misunderstood — and valuable — benefits in OEM-EMS provider relationships.

4. Fewer Expedites, Less Firefighting

Forecast horizon + Kanban flow creates early warning before shortages occur.

What OEMs see

- Fewer hot-shot shipments

- Lower premium freight

- Fewer spot buys

- Less chaos in procurement and production

This directly reduces total supply-chain cost.

5. Better CM Capacity and Pricing for the OEM

When CMs can plan labor and material in advance:

- Overtime spikes drop

- Quality improves

- Overhead stabilizes

What OEMs see

- Better pricing leverage

- Higher reliability

- Fewer surprises

This is why strong electronics contract manufacturing partners push for forecast-driven Kanban models.

6. Clear Accountability Between OEM and EMS Partner

Monthly forecast + Kanban creates a clean governance model:

| Area | OEM | EMS |

|---|---|---|

| Demand outlook | Rolling monthly forecast | Capacity & constraint feedback |

| Execution trigger | Kanban pull | Replenishment |

| Inventory sizing | Approve bin size | Manage bins |

| Exceptions | Forecast changes | Supply-risk alerts |

What OEMs see

- Fewer disputes over demand ownership

- Cleaner contracts and Supplier Liability Agreements (SLAs)

- Clear financial and inventory responsibility boundaries

- Stronger, more professional partnership behavior

This clarity is one of the most underrated benefits of Kanban-driven OEM-EMS relationships.

7. Reduced Excess, Obsolete, and Stranded Inventory

Because:

- Inventory is capped by bin size

- Forecasts are refreshed monthly

- Engineering and demand changes often impact future bins — not large committed builds

What OEMs see

- Lower excess and obsolete (E&O) inventory write-offs

- Easier engineering change order (ECO) implementation

- Cleaner balance sheets for both the OEM and the EMS partner

This is especially critical in electronics manufacturing, where component lifecycles are short and revisions are frequent.

8. Improved Trust and Data Quality Over Time

A forecast-driven Kanban system creates a self-reinforcing improvement loop between OEMs and their electronics contract manufacturing partners.

When forecasts are used for planning instead of punishment:

- OEMs provide more honest demand signals

- EMS partners plan capacity and material more accurately

Kanban execution data then improves:

- True consumption visibility

- Real lead-time accuracy

- Reorder point reliability

What OEMs see

- Better decision-making

- Reduced buffers and safety stock

- A higher-maturity, more predictable supply chain

Over time, this shifts the relationship from transactional to strategic — which is exactly what OEMs want from high-performing electronics manufacturing service providers.

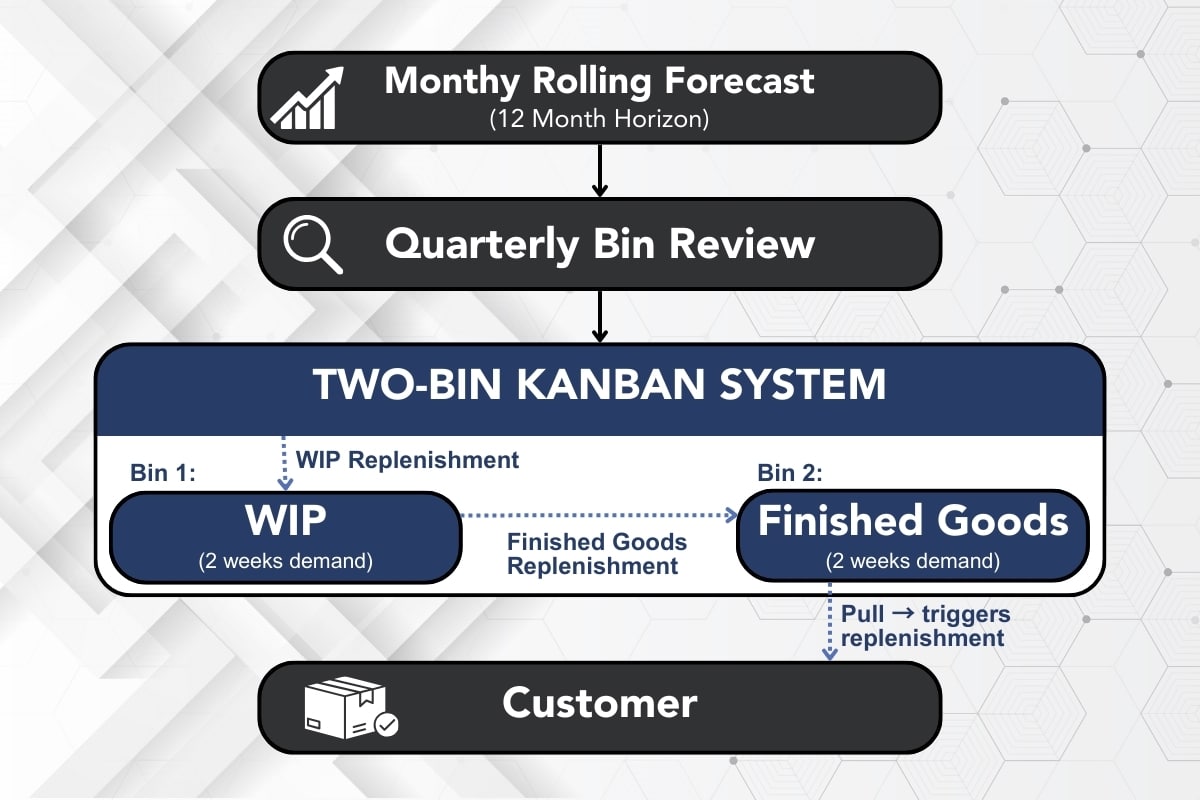

How the Model Works in Practice

- OEM provides a 12-month rolling forecast

- Updated monthly

- Non-binding beyond near-term fence

- EMS partner plans capacity and long-lead buys across

- 2-bin Kanban governs execution

- Bin 1 = consumption

- Bin 2 = replenishment buffer

- Bin size reviewed quarterly

- Adjusted for demand, lead time, and variability

- Exceptions managed, not normalized

- Expedites are signals, not standard practice

Bottom Line for OEMs

When implemented correctly by a capable electronics manufacturing service provider, monthly forecasts + 2-bin Kanban system allow OEMs to:

This is not a shop-floor tactic — it is a supply-chain control system for modern electronics manufacturing.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.