Cable Assembly and Wire Harnesses: Best Practices for Consistent Performance

- Cable Assembly vs. Wire Harness: Understanding the Difference

- Design for Manufacturability (DFM): The First Step Toward Consistency

- Documentation and Revision Control

- Material Traceability and Quality Standards

- Process Control and Operator Training

- Environmental and Mechanical Considerations

- Testing and Validation for Reliability

- Continuous Improvement Through Feedback Loops

- Supply Chain and Sourcing Best Practices

- Conclusion

- Partner with Federal Electronics

Cable assemblies and wire harnesses are the backbone of modern electrical and industrial systems. In today’s electronics manufacturing environment, reliability isn’t optional—it’s engineered. Whether powering aerospace systems, industrial automation, or medical devices, the performance of a cable assembly or wire harness directly affects product safety, longevity, and compliance. Even minor inconsistencies in materials or workmanship can lead to failures that ripple across production schedules and supply chains.

Understanding and applying best practices in cable assembly and wire harness manufacturing ensures every build meets the same standard of quality—every time.

Cable Assembly vs. Wire Harness: Understanding the Difference

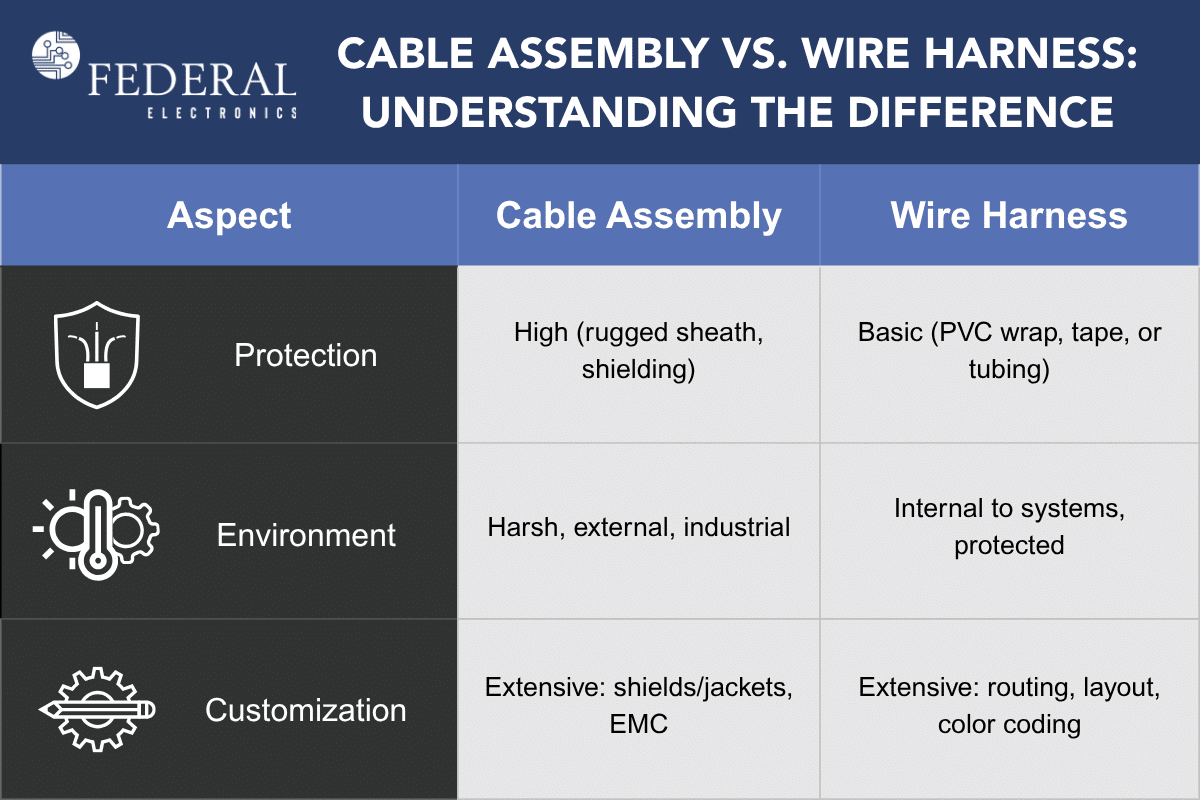

Though often used interchangeably, these two terms refer to distinct components that serve different roles in electrical systems.

- A wire harness is an organized bundle of discrete wires, connectors, and terminals designed to route electrical signals efficiently within a system. It typically uses low-voltage wiring secured by cable ties, lacing, or heat-shrink tubing to maintain structure.

- A cable assembly, by contrast, encases its wires in a unified outer sheath or jacket for added protection against heat, abrasion, and environmental stress. These assemblies often integrate shielding, strain relief, and molded connectors to support harsher conditions or higher-performance requirements.

The distinction matters: choosing the right configuration for your application affects not only reliability but also manufacturability, maintenance, and cost over time.

Design for Manufacturability (DFM): The First Step Toward Consistency

A reliable product starts with a reliable design. Applying Design for Manufacturability (DFM) principles to cable assemblies and wire harnesses helps engineers identify potential issues before production begins.

Key DFM considerations include:

- Connector compatibility –Verify mechanical fit and electrical performance early to prevent late-stage rework.

- Bend radius and routing – Maintain minimum bend radii to avoid conductor damage or signal loss.

- Material selection – Match wire insulation, shielding, and jacketing to the operating environment (temperature, vibration, chemical exposure).

- Standardization – Where possible, use common components and connector types to simplify sourcing and quality control.

By collaborating closely with manufacturing partners during the design phase, OEMs ensure drawings translate seamlessly into repeatable production processes and designs take advantage of the latest process technologies to optimize cost and yields.

Documentation and Revision Control

Consistent performance depends on accurate documentation. Every wire harness and cable assembly should start with detailed specifications that include:

- Wiring schematics and wire run lists

- Bills of Material and Approved Supplier Lists

- Assembly drawings that indicate the final product configuration.

From this technical data package, a qualified electronics manufacturing service provider will generate:

- Detailed assembly process instructions that include:

- Wire cut lengths and labeling requirements

- Termination/Crimping requirements (tooling, strip lengths, crimp heights, pull tests)

- Connector pin-outs and assembly details

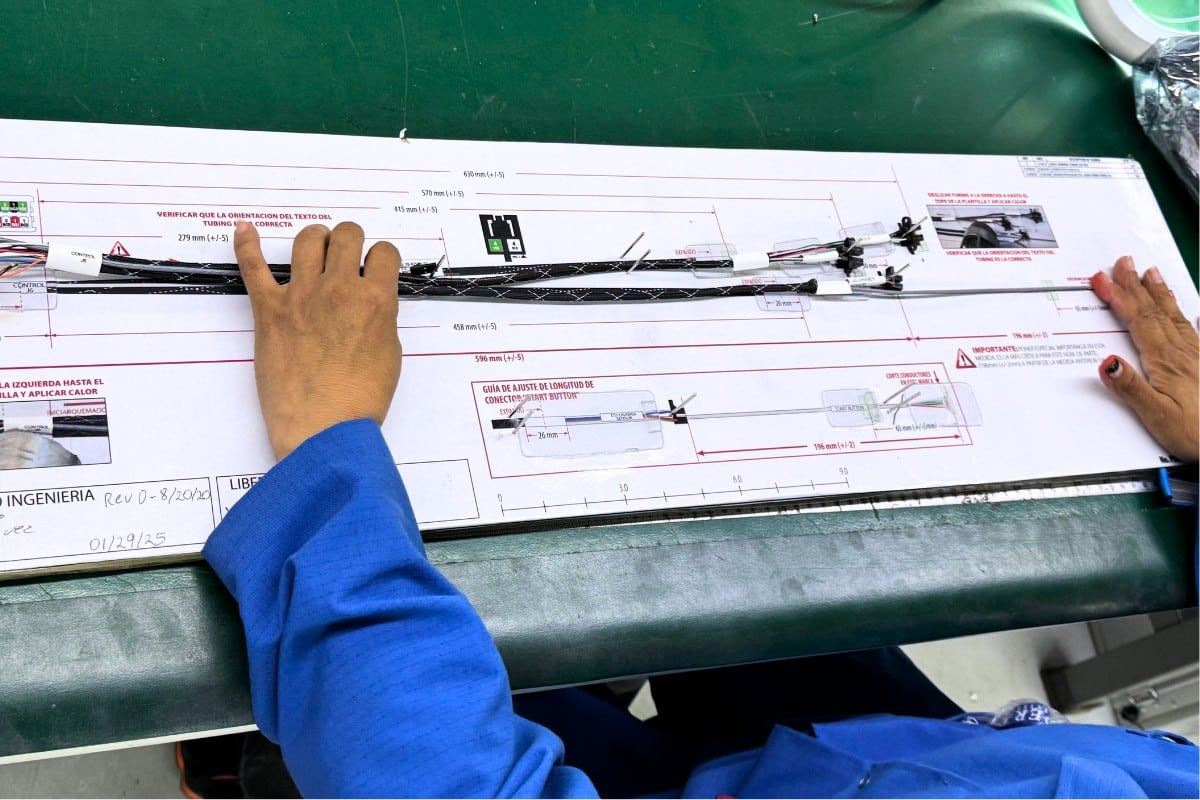

- Assembly-specific fixtures (harness boards, alignment fixtures, etc.)

- Quality control plans

- Identification of critical inspection points and methods

- Test protocols with associated fixtures and programs

- Torque specifications if applicable

To avoid variation between builds:

- Maintain digital revision histories that track changes across drawings, materials, and work instructions.

- Implement barcoding or ERP-linked traveler systems to control process flow.

Well-structured documentation minimizes human error and ensures that every technician—from prototype to full production—follows the same validated process.

Material Traceability and Quality Standards

Modern supply chains demand visibility. Implementing traceability systems within cable assembly production ensures that each lot can be traced back to its raw materials and vendors. This is critical for maintaining compliance and enabling quick containment if an issue arises.

To verify workmanship and safety, leading manufacturers follow globally recognized standards such as:

- IPC/WHMA-A-620,Requirements and Acceptance for Cable and Wire Harness Assemblies, which defines acceptable workmanship criteria for soldering, crimping, lacing, and insulation.

- J-STD-001,Requirements for Soldered Electrical and Electronic Assemblies, which specifies soldering materials, processes, and inspection requirements for high-reliability products.

Adherence to these standards helps manufacturers deliver custom wiring harness solutions that perform consistently under demanding conditions—from defense electronics to industrial robotics.

Process Control and Operator Training

Repeatability depends on process discipline. Establishing documented workflows and training ensures every build follows the same validated steps:

- Wire Preparation – Automated cutting, stripping, and marking equipment ensure precision and consistency.

- Termination and Crimping – Regular calibration of tooling prevents variation in electrical and mechanical integrity.

- Routing and Tying – Proper lacing and bundling minimize strain and improve airflow in enclosures. The use of controlled fixtures and harness boards decreases variation between lots.

- Soldering and Potting – Controlled soldering processes aligned with J-STD-001 requirements eliminate cold solder joints, contamination and other process related issues.

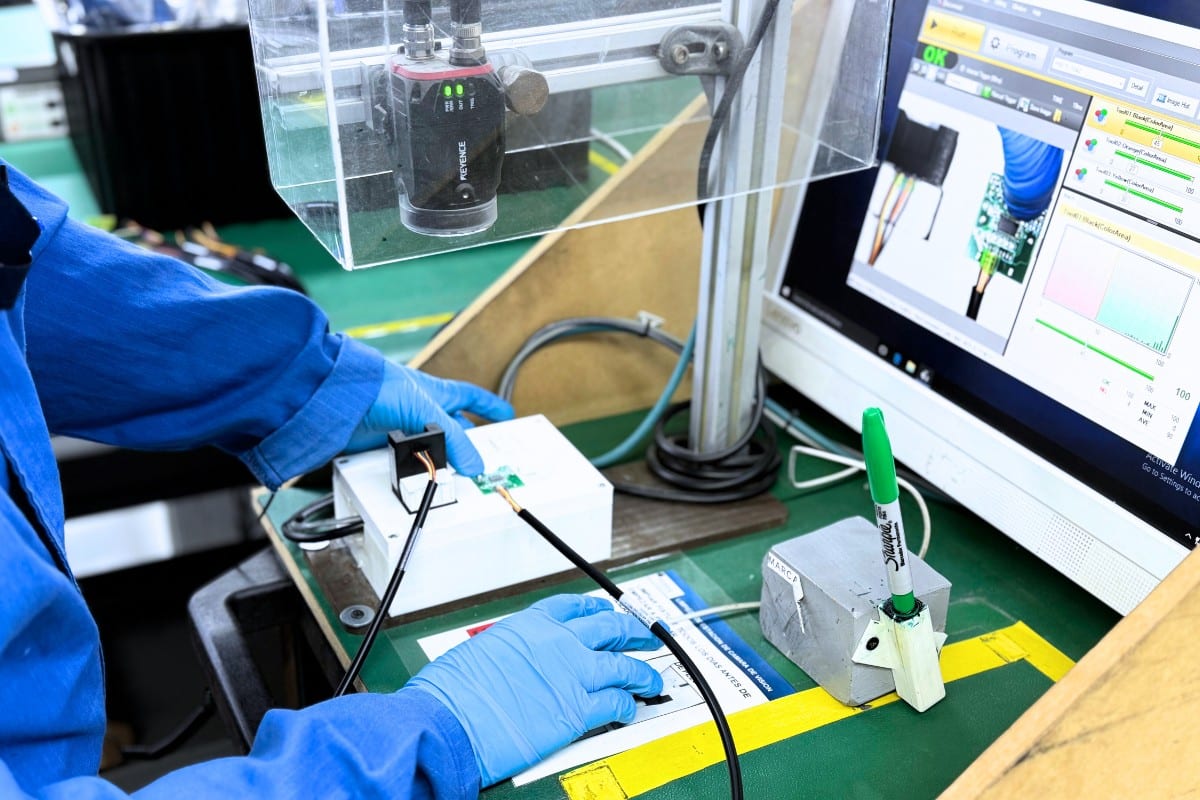

- Inspection and Test – 100% continuity testing, pull testing, and visual inspection confirm assembly integrity before shipment.

Periodic audits and operator re-certifications reinforce compliance with internal and external quality systems.

Environmental and Mechanical Considerations

High-reliability applications demand that cable and harness designs account for the environments they serve.

- Temperature and humidity – Choose insulation and jackets with proven dielectric and thermal stability.

- Flexibility and motion – For dynamic applications such as robotics or machinery, select fine-strand conductors and torsion-rated cables.

- EMI/RFI protection – Incorporate braided shields, foil wraps, or ferrite components to reduce electromagnetic interference.

- Ingress protection – Use grommets, over-molding/potting, or sealed connectors when exposure to fluids, dust, or outdoor conditions is likely.

Early material selection not only safeguards function but also supports longer lifecycle performance and reduced maintenance costs.

Testing and Validation for Reliability

Testing verifies that the build matches both the design and the application environment. Comprehensive validation should include:

- Continuity and insulation-resistance testing to detect open circuits or shorts.

- Hi-pot testing for dielectric strength in high-voltage assemblies.

- Pull and retention testing to confirm mechanical crimp integrity.

- Environmental testing, such as vibration, temperature cycling, or salt-fog exposure, for mission-critical applications.

Automated test fixtures linked to serialized data capture provide traceable results that support long-term reliability analysis.

Continuous Improvement Through Feedback Loops

High-performing manufacturers view quality as a moving target. Each production run provides data that can refine the next.

Establishing closed feedback loops between production, engineering, and quality teams enables:

- Early identification of recurring defects.

- Root-cause analysis with corrective and preventive actions.

- Real-time process monitoring for trend detection.

By combining statistical process control with robust QMS tools, manufacturers continually raise yields and reduce field returns—critical metrics for both engineering and procurement teams.

Supply Chain and Sourcing Best Practices

For OEMs, maintaining supply continuity is as important as technical performance. Reliable harness suppliers balance cost efficiency with component availability by:

- Qualifying multiple suppliers for critical parts.

- Managing obsolescence through proactive part forecasting and access to latest supplier information.

- Using regional manufacturing partners to reduce logistics lead times.

Global disruptions have underscored the need for resilient supply networks. Selecting suppliers who demonstrate flexibility and transparent communication ensures schedules stay on track even during market volatility.

Conclusion

In the interconnected world of modern electronics, a dependable cable assembly or wire harness is far more than a collection of wires and connectors—it’s the circulatory system of every complex product.

By following established industry standards and proven cable assembly best practices, maintaining robust documentation, and prioritizing quality at every stage—from design through testing—manufacturers can ensure consistency, reliability, and compliance across every build.

For engineers and supply-chain professionals alike, understanding these best practices is essential to specifying partners and processes that deliver consistent performance today—and in the future.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.