What is Electronics Manufacturing Services (EMS)? A Complete Guide for OEMs

- What is Electronics Manufacturing?

- What are Electronics Manufacturing Services (EMS)?

- EMS Providers vs OEMs: Understanding the Difference in Electronics Manufacturing

- Industries Federal Electronics Supports with EMS Solutions

- Benefits of Electronics Manufacturing Services (EMS)

- 7 Things OEMs Must Know Before Selecting an EMS Partner

- Federal Electronics: Built for Complexity, Trusted for Reliability

- The Future of Electronics Manufacturing

- Partner with Federal Electronics

When it comes to getting products to market, Original Equipment Manufacturers (OEMs) face constant challenges: global competition, supply chain disruptions, and evolving compliance requirements. Many OEMs turn to electronics manufacturing service (EMS) providers to solve these challenges.

An EMS provider is more than just an assembler — it is a strategic electronics manufacturing partner that helps OEMs scale production, ensure quality, and safeguard their supply chain. At Federal Electronics, we differentiate ourselves through dual-site operations in the U.S. and Mexico, vertically integrated EMS capabilities that eliminate margin stack-up, and a proven focus on supply chain resiliency and risk mitigation.

What is Electronics Manufacturing?

Electronics manufacturing is the process of producing electronic assemblies, sub-assemblies, and finished systems. This includes:

- Printed Circuit Board Assembly (PCBA)

- Cable & wire harness assembly

- Electromechanical integration & box build assembly

- Systems integration

- Testing and inspection

- Distribution and logistics

An electronics manufacturing service provider extends its influence beyond production by offering supply chain management, design-for-manufacturability (DFM), and lifecycle support.

What are Electronics Manufacturing Services (EMS)?

Electronics manufacturing services (EMS) represent the full scope of outsourcing capabilities available to OEMs. EMS providers support OEMs with:

- Higher-volume/lower-mix to lower-volume/higher-mix manufacturing models

- Regulatory compliance and certifications

- Proactive supply chain management

- Value-added engineering services

- Customized component pipelining and finished product Kanban programs

Choosing the right EMS provider is critical for OEMs that want to solidify their strategic supply chain while ensuring business continuity and risk mitigation.

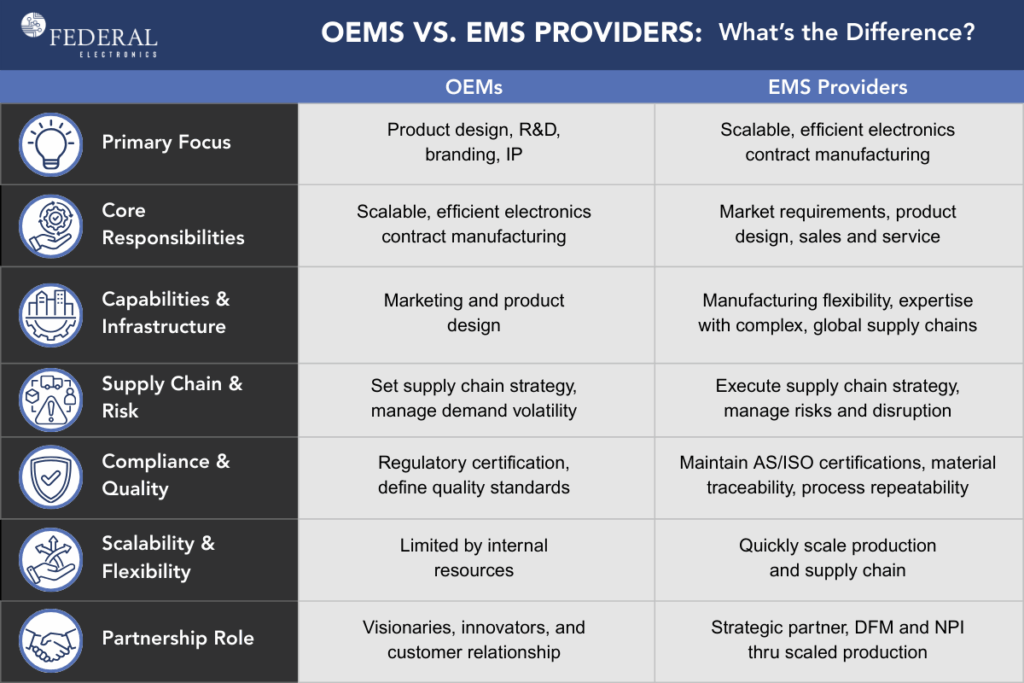

EMS Providers vs OEMs: Understanding the Difference in Electronics Manufacturing

OEMs typically focus on product design, intellectual property (IP), and innovation, while EMS providers focus on manufacturing execution, scalability, compliance, and risk management.

At Federal Electronics, we act as an extension of the OEM team — delivering contract electronics manufacturing solutions while ensuring transparency, compliance, and supply chain security.

Industries Federal Electronics Supports with EMS Solutions

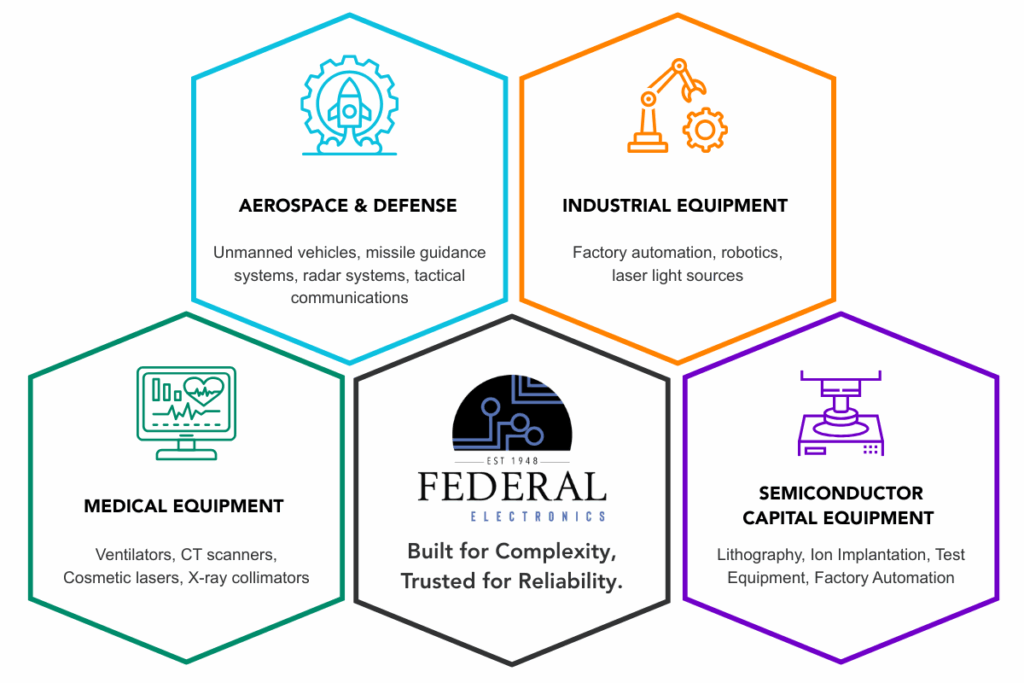

While EMS providers can serve many markets, Federal Electronics specializes in high-reliability industries where precision, compliance, and resilience are essential.

Aerospace & Defense Manufacturing

AS9100 and ITAR-certified EMS for avionics, communications, and mission-critical defense systems.

Medical Equipment Manufacturing

Strict FDA compliance standards, full traceability, and advanced quality systems for diagnostic, monitoring, and surgical devices.

Industrial Equipment Manufacturing

High-mix, complex assemblies engineered for automation systems, robotics, and motion control applications.

Semiconductor Capital Equipment Manufacturing

Precision harnesses, PCBAs, subsystems, and assemblies supporting advanced semiconductor equipment — built with supply chain resilience in mind.

Benefits of Electronics Manufacturing Services (EMS)

Working with an EMS provider delivers clear advantages to OEMs:

- Cost Efficiency & Scalability – Eliminate the overhead of in-house facilities.

- Supply Chain Risk Mitigation – Reduce exposure to global disruptions.

- Quality & Compliance – ISO and AS certifications, advanced inspection, and testing.

- Engineering & DFM Support – Collaborative services to improve manufacturability and reduce costs.

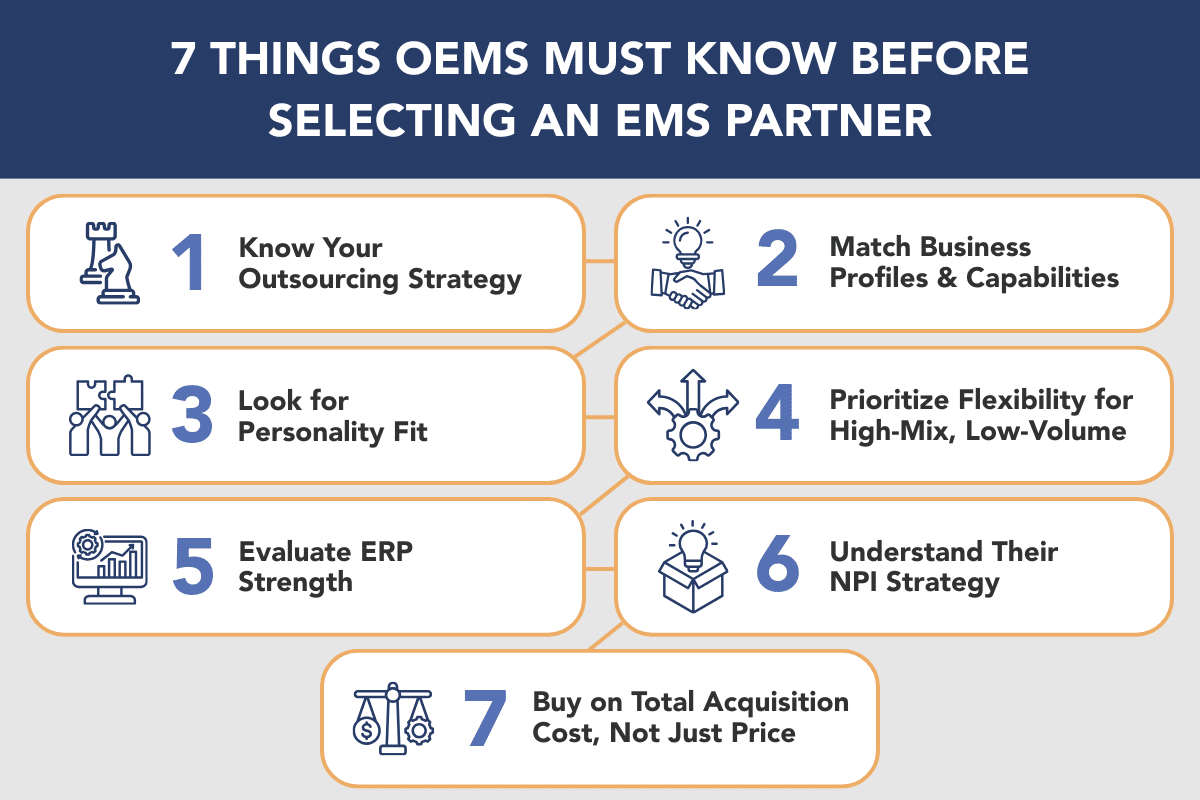

7 Things OEMs Must Know Before Selecting an EMS Partner

When evaluating contract electronics manufacturers, keep these principles in mind. They come directly from Federal’s guide, 7 Things You Must Know Before Selecting an EMS Partner:

1. Know Your Outsourcing Strategy

Start by defining whether you’ll outsource PCBAs, cables, or higher-level turnkey builds. Will you start at a sub-assembly level and evolve to higher level assemblies? Your EMS partner should be able to scale with you as your strategy evolves.

2. Match Business Profiles & Capabilities

The right EMS provider has the infrastructure, engineering bandwidth, and ECO process to support your product mix, engineering activity, and schedule variability expectations.

3. Look for Personality Fit

Beyond technical capability, culture matters. Choose a partner whose communication style and values align with how you want to work—whether tactical or strategic.

4. Prioritize Flexibility – Especially for Higher-Mix, Lower-Volume Products

Complex, configurable products require suppliers who can rapidly adjust production levels, manage variability, and still meet quality and delivery requirements.

5. Evaluate Enterprise Resource Planning (ERP) Strength

Robust ERP systems drive inventory control, capacity planning, and schedule responsiveness. Weak ERP can create bottlenecks, late deliveries, and higher costs.

6. Understand Their New Product Introduction (NPI) Strategy

A capable EMS partner supports prototypes, DFM feedback, and scale-up. If you need help building products faster and more cost-effectively, confirm they have NPI engineering assets that are up to the task, including the ability to manage the project throughout the development cycle.

7. Buy on Total Acquisition Cost, Not Just Price

Unit price is only one piece of the puzzle. Consider quality yields, delivery performance, flexibility, and the hidden costs of late shipments or field failures.

DOWNLOAD THE FULL GUIDE: 7 Things You Must Know Before Selecting an EMS Partner

Federal Electronics: Built for Complexity, Trusted for Reliability

Federal Electronics is more than an EMS provider — we are a strategic partner trusted by OEMs in complex, high-reliability markets.

Our core differentiators are:

1. Supply Chain Approach & Risk Mitigation – Proactive strategies to manage shortages, logistics issues, and global risk.

2. Dual-Site Operations – Mirrored facilities in the U.S. and Mexico, providing redundancy, flexibility, and scalability.

3. Vertically Integrated EMS Capabilities – Integrated operations across PCBA, cable & wire harnesses, and box build assembly give us unparalleled control over the entire supply chain and assembly processes, reducing costs and improving efficiency by eliminating margin stack-up.

By choosing Federal Electronics as your electronics manufacturing service provider, you gain a partner built to deliver reliability, resilience, and results.

The Future of Electronics Manufacturing

The electronics manufacturing service industry is evolving quickly with reshoring, digital transformation, and sustainability initiatives.

For OEMs, success will depend on partnering with EMS providers who can align with their supply chain strategy while developing systems and processes to support their unique challenges.

At Federal Electronics, we deliver manufacturing solutions built for complexity, trusted for reliability, and ready for the future.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.