The Future of Electronic Manufacturing Services and OEM Partnerships: From Vendors to Strategic Allies

- Why the EMS–OEM Relationship is Evolving

- From Transactional Vendors to Strategic Allies

- The Benefits of Strategic EMS Partnerships

- Why OEMs Need Strategic EMS Partnerships Now

- Federal Electronics: Building Strategic Partnerships with OEMs

- Conclusion: The Future Is Collaborative

- Partner with Federal Electronics

Why the EMS–OEM Relationship is Evolving

Global supply chains are under pressure like never before. Rising tariffs, labor shortages, and geopolitical instability, have made it clear that resilience—not just cost efficiency—determines which companies thrive.

For decades, Original Equipment Manufacturers (OEMs) often treated Electronic Manufacturing Ser vices (EMS) providers as vendors—partners in name only, tasked with fulfilling production orders at the lowest possible cost. That transactional model is rapidly becoming outdated.

Today, the most forward-thinking companies recognize that success requires more than outsourcing production. It requires electronics manufacturing supply chain collaboration built on transparency, trust, and long-term alignment. OEMs need EMS providers who act as strategic allies, not just contract manufacturers.

From Transactional Vendors to Strategic Allies

The traditional EMS model revolved around contract manufacturing: OEMs designed, EMS providers built, and both sides moved on. That approach is still common, but it is no longer sufficient for industries facing rapid innovation cycles, regulatory complexity, and global supply chain risks.

Forward-looking OEMs are asking EMS providers to do more. They want electronic manufacturing services OEM partnerships that integrate engineering expertise, advanced order planning and fulfillment strategies, compliance leadership, and supply chain resilience.

This shift represents the rise of strategic manufacturing alliances—relationships where OEMs and EMS providers jointly shape solutions, share risk, and innovate together. In this model, the EMS provider is no longer just a vendor. It is an extension of the OEM’s supply chain strategy.

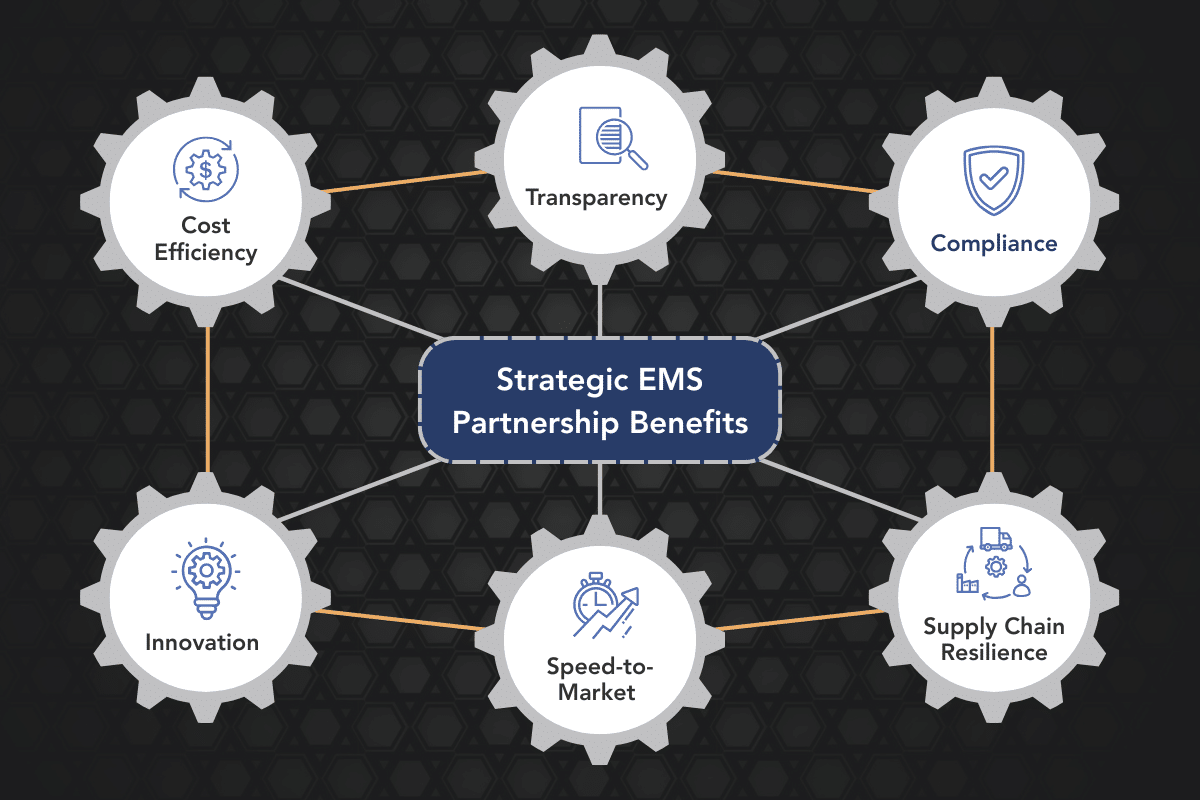

The Benefits of Strategic EMS Partnerships

- Supply Chain Resilience

EMS providers with multi-site or dual-site capabilities give OEMs flexibility in uncertain times. A partner with both U.S. and nearshore capacity (like Mexico) can mitigate risk from shipping bottlenecks, tariffs, or geopolitical disruptions. - Innovation & Engineering Support

Strategic electronics manufacturing service partners bring value before production begins. By offering Design for Manufacturability, Assembly, and Test (DFx), New Product Introduction (NPI) support, and proactive sourcing practices to minimize the impact of component obsolescence and directed source/sole source suppliers, EMS providers accelerate innovation while reducing costly redesigns. - Compliance & Quality

As industries like aerospace, defense, and medical devices face increasingly strict regulations, EMS providers must offer more than quality control—they must provide quality assurance that aligns with U.S. and international standards. Strategic partners embed compliance at every stage. - Cost Efficiency without Compromise

Traditional outsourcing often leads to margin stacking, where costs build up across multiple suppliers. A vertically integrated EMS partner streamlines the process, delivering efficiency without sacrificing quality or oversight. - Shared Data & Transparency

Modern OEMs expect digital alignment. Strategic EMS partnerships include ERP integration and real-time metrics. Transparency strengthens trust while enabling faster, data-driven decisions.

Why OEMs Need Strategic EMS Partnerships Now

The risks of relying on transactional vendor relationships are mounting. In the last five years, OEMs relying solely on offshore production have experienced shipping delays stretching from weeks to months, surging freight costs, and volatile tariffs.

Meanwhile, nearshoring and onshoring trends highlight the benefits of proximity, compliance assurance, and faster lead times. OEMs increasingly realize that electronic manufacturing services OEM partnerships are not a luxury—they are a necessity for long-term competitiveness.

In fact, many supply chain executives now view their EMS providers as strategic manufacturing allies who safeguard their ability to deliver products reliably, compliantly, and profitably.

Federal Electronics: Building Strategic Partnerships with OEMs

At Federal Electronics, we have been evolving with our customers for more than 60 years. Our approach goes far beyond transactional outsourcing—we provide true strategic partnerships.

- Dual-Site Operations (U.S. & Mexico): Our Cranston, Rhode Island facility specializes in high-reliability manufacturing for defense, medical, and other highly regulated industries requiring strict oversight. Our Hermosillo, Mexico facility delivers cost-effective, scalable solutions close to U.S. supply chains, enabling shorter lead times and reduced logistics costs.

- Vertical Integration: Our electronics manufacturing services span Printed Circuit Board Assembly (PCBA), Cable & Wire Harness Assembly, electromechanical builds, industrial control panels, and full system integration. By bringing these capabilities together within one company, we reduce margin stacking, improve efficiency, and simplify the supply chain.

- Collaborative Approach: We see ourselves as an extension of your team—focused on resilience, compliance, and speed-to-market.

This combination of compliance, scalability, and supply chain resilience positions Federal as more than an EMS provider. We are a strategic ally for OEMs navigating today’s complex landscape.

Conclusion: The Future Is Collaborative

The EMS industry is at a turning point. OEMs no longer want vendors who simply fulfill orders. They want strategic EMS partnerships that align with their long-term goals, safeguard their supply chains, and fuel innovation.

The future of electronic manufacturing will be defined by electronics manufacturing supply chain collaboration—alliances where EMS providers and OEMs innovate together, share risk, and drive mutual success.

At Federal Electronics, we are proud to be at the forefront of this shift. By blending onshore and nearshore capabilities, vertical integration, and compliance-first operations, we give OEMs the confidence that their manufacturing partner is truly an extension of their strategy.

Ready to transform your vendor relationship into a strategic alliance? Contact Federal Electronics today to explore how our collaborative model can strengthen your supply chain and your competitive advantage.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.