Nearshoring vs Offshoring in Electronics Manufacturing: What’s Best for Your Program

- Introduction: Why Location Strategy Matters in Electronics Manufacturing

- What is Offshoring in Electronics Manufacturing?

- What is Nearshoring in Electronics Manufacturing?

- Nearshoring vs Offshoring: Key Factors to Consider

- Why Federal Electronics Chooses Dual-Site (U.S. & Mexico)

- Why Mexico Matters for Nearshoring

- Conclusion: Making the Right Choice

- Partner with Federal Electronics

Introduction: Why Location Strategy Matters in Electronics Manufacturing

Where your electronics manufacturing happens is as critical as how it happens. The choice between nearshoring vs offshoring impacts cost, risk, and speed-to-market. In today’s volatile global economy, supply chain strategy is no longer just about cost — it is about resilience, agility, and long-term sustainability. Global disruptions such as the COVID-19 pandemic, rising tariffs, shipping bottlenecks, and escalating logistics costs have reshaped how OEMs evaluate their electronics manufacturing programs. According to the World Economic Forum’s Global Risks Report, supply chain fragility and geopolitical instability remain among the top global business risks.

For decades, offshoring was the dominant model. But today, many companies are reevaluating and turning to nearshoring and onshoring as ways to strengthen their supply chains. Choosing the right model is one of the most critical decisions supply chain managers and executives face when mapping out production strategy.

At Federal Electronics, we don’t believe OEMs should have to compromise. Our dual-site operations in the U.S. and Mexico are fully mirrored — both facilities deliver the same levels of compliance, quality, scalability, and efficiency. Customers choose production location based on their business drivers, whether that’s regulatory requirements, cost optimization, or proximity to market.

What is Offshoring in Electronics Manufacturing?

Offshoring refers to shifting production to lower-cost regions—most commonly Asia (China, Vietnam, Malaysia) or Eastern Europe. This strategy surged in popularity during the late 20th century as OEMs pursued aggressive cost savings through reduced labor expenses and large-scale capacity.

Benefits of Offshoring

- Lower labor costs – Asia remains one of the most cost-competitive regions for electronics assembly and manufacturing.

- Massive infrastructure – Decades of investment have built robust supply bases, with wide availability of raw materials, components, and labor.

- Established global trade networks – Mature logistics hubs and long-standing international partnerships streamline global exports.

Risks of Offshoring

- Longer lead times – Shipping across oceans can take weeks, slowing speed-to-market and responsiveness.

- Supply chain vulnerability – Natural disasters, pandemics, and geopolitical instability can severely disrupt offshore supply lines.

- Intellectual property (IP) and quality risks – Varying regulatory enforcement may lead to IP theft, counterfeiting, or inconsistent compliance.

What is Nearshoring in Electronics Manufacturing?

Nearshoring means relocating production closer to end markets—for U.S. companies, this often means nearshoring to Mexico or other Latin American countries. The strategy reduces distance, improves responsiveness, and strengthens regional presence.

Benefits of Nearshoring

- Shorter lead times – Reduced transportation distances mean faster time-to-market.

- Lower logistics costs – Less reliance on ocean freight minimizes shipping expenses and transportation volatility.

- Greater supply chain visibility – Geographic proximity allows OEMs to monitor and manage operations more effectively.

- Cultural and time zone alignment – Shared business hours and language compatibility make collaboration smoother.

- Stronger IP protections – U.S.-Mexico trade agreements often provide greater safeguards than some offshore markets.

Challenges of Nearshoring

- Higher labor costs than Asia – While lower than U.S. costs, nearshore wages are generally higher than traditional offshore markets, although of late the gap has lessened. The introduction of tariffs on both countries and specific industries has also played a role in reducing the cost differential.

- Capacity gaps in some advanced technologies – Certain highly specialized components may still require sourcing from Asia.

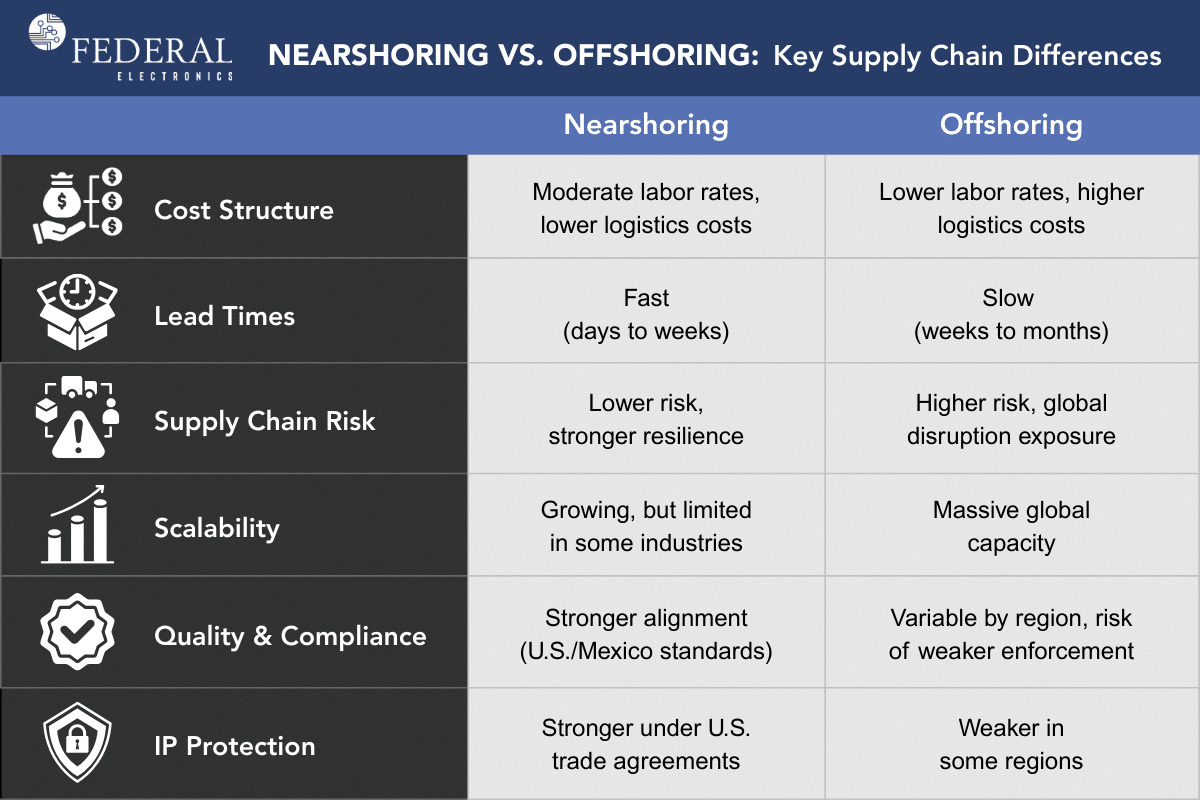

Nearshoring vs Offshoring: Key Factors to Consider

When evaluating nearshoring vs offshoring manufacturing, companies should balance cost savings with flexibility, risk, and long-term resilience.

For many OEMs, the decision is no longer binary. While some continue to offshore in pursuit of lower labor costs, more are realizing the limitations of that model — especially for products destined for the western hemisphere. The strongest programs today emphasize onshoring and nearshoring to optimize costs, remain compliant with regulations, and secure a robust supply chain while manufacturing products in or near the region where they will be sold.

Why Federal Electronics Chooses Dual-Site (U.S. & Mexico)

At Federal Electronics, we believe OEMs should not have to compromise between cost efficiency and compliance. That is why we have built a mirrored dual-site model in the U.S. and Mexico — each site capable of handling the same high-reliability builds with equal quality and certifications.

- U.S. Facility (Cranston, RI): Often selected when programs must remain domestic due to regulatory requirements, customer preference, or supply chain strategy.

- Mexico Facility (Hermosillo): Frequently chosen for cost optimization, shorter logistics routes, and competitive labor advantages.

Both facilities are fully aligned in compliance, certifications, and quality systems. The difference is not what each site can do, but why customers choose one location over the other. Together, they form a resilient dual-site network that reduces supply chain risk and gives OEMs true flexibility.

Watch Video: Federal Electronics’ Unique Solution to Offset Growing Costs

Why Mexico Matters for Nearshoring

For OEMs weighing nearshoring options, Mexico is the clear leader in electronics manufacturing. Its strong alignment with U.S. regulatory standards, robust trade agreements such as United States-Mexico-Canada Agreement (USMCA), and proximity to North American markets make it uniquely suited for complex, high-reliability builds.

Federal’s Hermosillo facility extends these advantages by operating in lockstep with our U.S. site. This mirrored approach gives OEMs seamless flexibility across borders — with equal assurance of compliance, supply chain resilience, and quality control every step of the way. Furthermore, as an extension of the hybrid model, higher labor content assemblies can be sourced in Mexico, then transferred to the U.S. for further integration into higher level assemblies, optimizing costs while satisfying customer requirements for on-shore production.

Conclusion: Making the Right Choice

By pairing U.S. and Mexico operations under a mirrored dual-site model, Federal delivers a hybrid solution that captures the benefits of onshoring and nearshoring — without the vulnerabilities of offshoring.

For OEMs weighing nearshoring vs offshoring, Federal Electronics’ dual-site electronics manufacturing services provide the flexibility to design a supply chain tailored to your needs — without compromise in quality, compliance, or scalability, no matter which site you choose.

Ready to strengthen your electronics manufacturing program? Contact Federal Electronics today to explore how our dual-site approach can help you balance cost, quality, and resilience.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.