Product Launch/ Transition Management

Accelerating Your Time to Market

Federal Electronics’ Product Launch and Transition Management Solution offers OEMs of complex, highly engineered products a comprehensive suite of services designed to speed up market entry and ensure consistent, reliable electronics manufacturing.

Project Management

Initial Engagement:

- Single Point of Contact: A dedicated NPI Program Manager will take lead of your project, collaborating with your team and aligning our internal resources to optimize manufacturing efficiency, establish a robust and resilient supply chain, and mitigate risks along the way.

- Team Approach: Subject matter experts from our engineering, supply chain, manufacturing, and quality assurance/test resources are assembled as appropriate based on the pre-defined scope, configuration, and manufacturing site(s) of your project.

Transparency and Accountability:

- Periodic and Structured Reviews: We provide transparency and track progress against expected outcomes, acting as a seamless extension of your operation.

Vertical Integration

Centers of Competency:

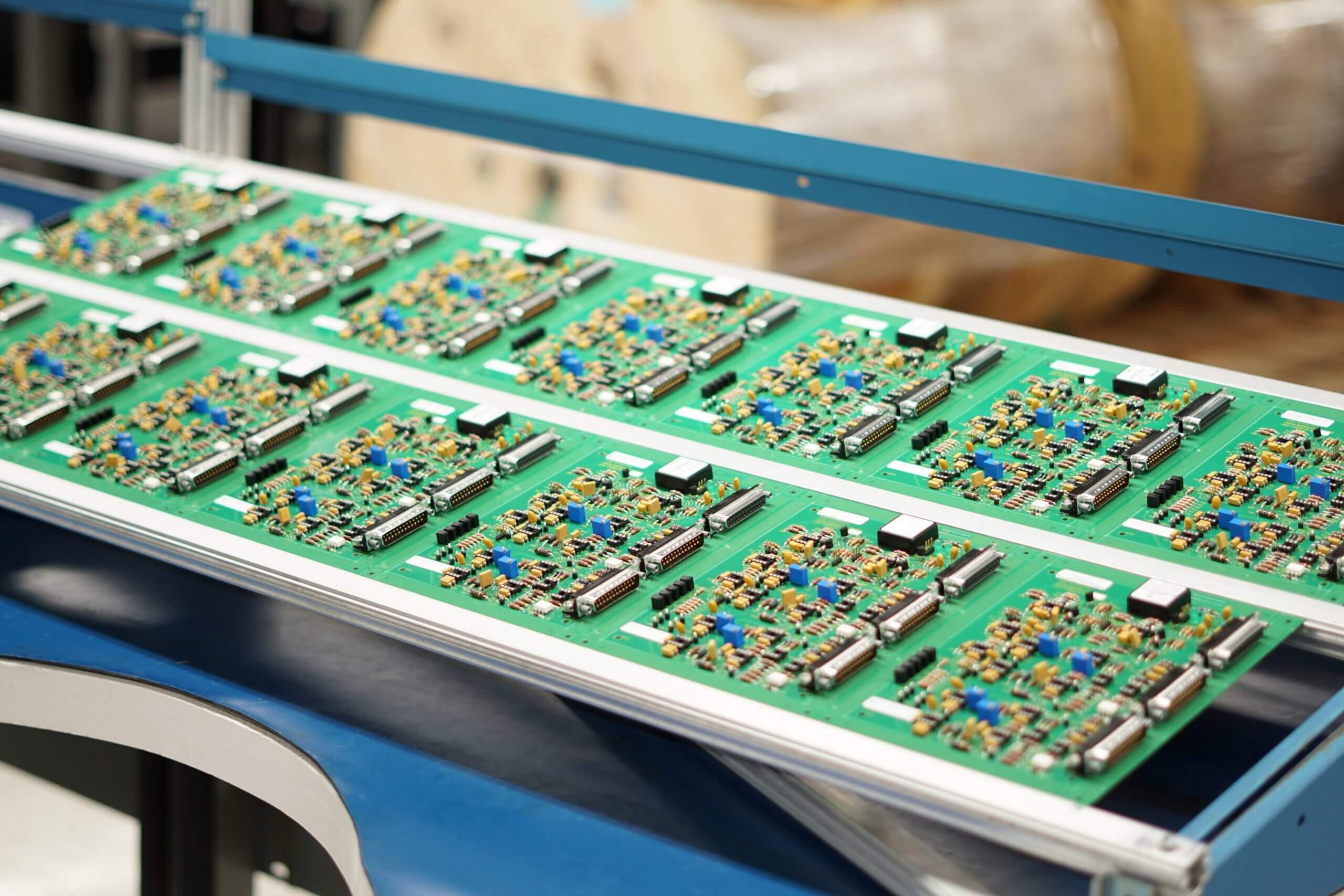

- Specialized Electronics Manufacturing: Our model includes expertise in a range of capabilities including higher-level assemblies, industrial control panels, box build assembly, electro-mechanical assemblies, precision mechanical assemblies, printed circuit board assemblies (PCBA), cable & wire harness assemblies, and fiber optic cable assemblies.

- Divide and Conquer: Documentation review, process development and quality control plans are developed in parallel for each assembly type within both manufacturing sites in order to facilitate shorter cycle times.

- DFx Methodologies: Our design and material selection processes identify risks early, ensuring manufacturability, quality, cost optimization, and material availability.

IT & ERP Integration

Centralized IT System:

- Integrated Operations: A centralized IT system connects engineering, supply chain, manufacturing, and quality operations across our domestic and lower-cost region sites, ensuring transparent communication throughout the process.

- ERP Integration: Our ERP system links engineering, supply chain, manufacturing, and quality

assurance across domestic and low-cost region sites, providing unprecedented transparency.

Custom Configurations:

- Constraint Identification: Using our finite scheduler and customer service impact module on a daily basis, we identify and resolve constraints in material availability, engineering resources, or manufacturing capacity, ensuring projects remain on time and on budget.

Specialized Supply Chain Network

Custom Fabricated Parts:

- Global Supply Chain: Our global supply chain includes sources for complex custom fabricated metal parts, strategically located in close proximity to both our US and Mexico facilities.

- Protecting Your Information: Employing the latest Cybersecurity protocols, we disseminate your technical information to our supply chain using secure and encrypted transmissions.

- Specialized Suppliers: Suppliers are selected based upon their ability to support the unique and specific requirements of higher complexity, highly engineered and highly regulated products.

Why Federal Electronics?

- Decades of Experience: With thousands of successful projects under our belt, we’ve expanded and refined our electronics manufacturing systems and processes to effectively address virtually any challenge you may encounter.

- Unmatched Expertise: We tackle challenges that other contract manufacturers can’t or won’t, building our reputation on delivering success.

- End-to-End Solutions: Comprehensive support from product launch through aftermarket services.

- Flexible and Customizable: Systems and processes tailored to your unique needs.

- Global Supply Chain: Expertise in sourcing complex component parts in lower volumes.

- Seamless Integration: Dedicated team acting as a virtual extension of your operation.

- Transparent Communication: Centralized IT system ensures clear communication throughout the process.

- Cost Management: Selective utilization of our Mexico facility produces unprecedented and highly effective cost management for complex electronic products.

- Centralized ERP System: Our nightly MRP and finite scheduling modules provide near real-time information, while keeping our two facilities working in tandem.

Partner with Federal Electronics

Overcome your most critical manufacturing challenges and contact us today to learn more about our customized solutions.