Navigating Supply Chain Disruptions: Semiconductors

Global disruptions in all facets of the supply chain have OEMs’ rethinking how and where they source material and manufacture their products. While electronic/electrical components have been particularly hard hit, no product category is more representative of availability challenges, or has received more media coverage, than semiconductors.

7 Methods to Handle Material Shortages

How Did We Get Here?

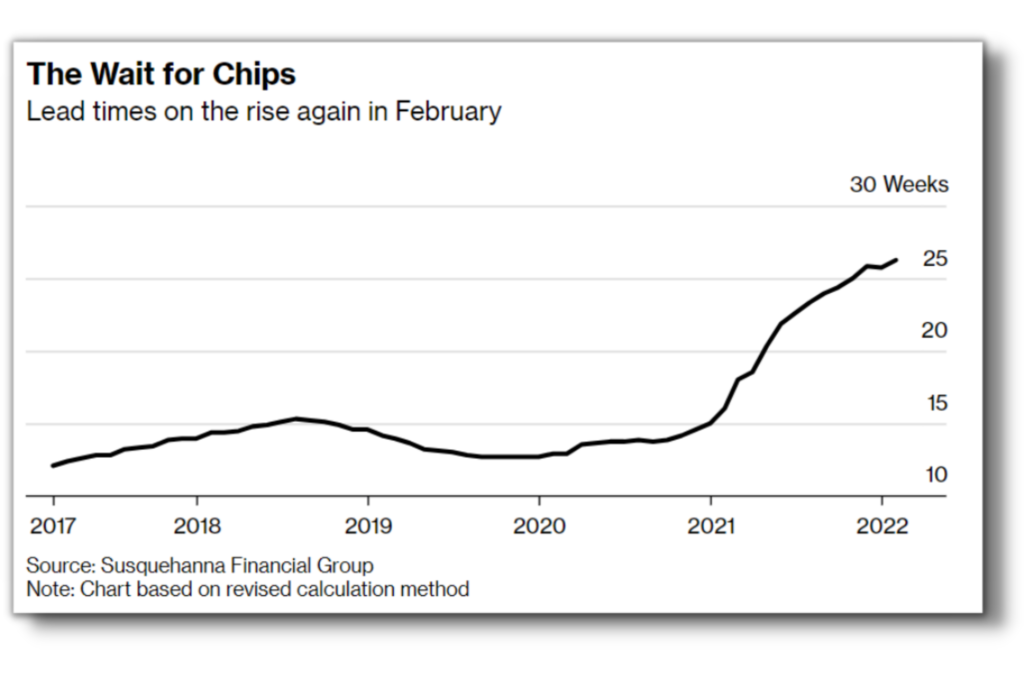

As electronic devices get smaller, more powerful and less expensive, the potential applications skyrocket creating explosive demand for components. Take semiconductors for example. “Typical lead times for semiconductor production can exceed four months for the products that are already well established in a manufacturing line” according to McKinsey & Company in May of 2021. Today, it is not uncommon to see lead times exceeding 40 to 50 weeks. In one notable instance, a semiconductor manufacturer stopped quoting lead times and even stopped accepting purchase orders due to capacity constraints.

While the growth in electronics is widely distributed, a significant percentage of the demand resides in the following areas:

- Automobile Electrification – Automobile manufacturers have rapidly increased the use of electronics as they continue to expand into EV product lines and introduce more sensors, which ultimately make cars “smarter” through options such as automated breaking, limited hands-free driving and lane-keep assistance with lane departure warnings. While cars currently average 1,400 chips per vehicle, EV’s with a full complement of “smart” options can have 5 to 6 times more chips than their fossil fuel counterparts.

- Consumer Devices– As Work-From-Home (WFH) increased during the pandemic, so too did the demand for home office equipment, including desktops, laptops, printers and all of the associated hardware necessary to remain productive while working remotely.

- Digital Infrastructure – As WFH continues, the demand for reliable telecommunications, including bandwidth, must keep pace. In addition, companies, both large and small, are increasing their digital footprint as they expand the gathering, processing, and storing of data. All of these factors create an environment of accelerated demand for the electronic components required to support this expansion.

With the added capacity constraints associated with the prolonged Covid 19 pandemic, the supply chain has failed to keep up with demand, resulting in critical material shortages that are expected to extend well into 2024. Thus, the conventional rules that historically drive a material pipeline have proven to be insufficient, and companies are introducing alternative and innovative methods to minimize the impact of supply chain uncertainty.

Federal’s Approach to Supply Chain Variability and Uncertainty

Federal Electronics focuses on quickly adapting to changing market conditions through the integration of our people, processes, and technologies. Here are the ways that Federal Electronics responds to supply chain variability and uncertainty:

- Daily Material Requirements Planning (MRP) – Running our MRP on a nightly basis ensures that the latest material demand data based upon customer priorities are captured and acted upon within 24 hours. Changes in demand (new orders and reschedules) for over 65% of planned parts are communicated to suppliers within 24 hours though the use of a supplier portal.

- Daily Production Scheduling – Resetting production schedules every evening based upon the current state of material availability, work cell labor allocation and utilization, and customer prioritization ensures we’re building the right complement of products at the right time.

- Driving To Need – Historically MRP systems would drive material to the longest lead time component and adjust as availability improved. To support demand requirements, Federal Electronics drives to our customers’ need dates and works proactively with them to address shortages that impact our ability to deliver to that need.

- Identifying Alternate Components – Federal Electronics utilizes software that compares electrical/physical parameters, suggests alternate components (especially semiconductors) based on the degree of similarity, and identifies current stock availability.

- Non-Franchised Sources – While our first choice is to use franchised distributors, when all franchised sources have been exhausted, some customers approve the use of brokers. In those instances, Federal Electronics has a documented, methodical process based upon AS6081 “Counterfeit Electronic Parts” with strict adherence to compliance requirements such as component testing when chain of custody is not available to broaden our sourcing options.

- Increasing The Demand Horizon – Obtaining longer demand horizons from our customers, coupled with an increase in our internal planning window, allows Federal Electronics to provide maximum visibility to the supply chain to help mitigate the impact of increasing lead times.

- Increasing The Supply Horizon – Placing orders well in advance of lead time, throughout the entire demand horizon regardless of lead time by expanding the planning window.

For decades, Federal Electronics has been working with some of the most ambitious OEMs in the industrial, defense, aerospace, and medical industries. As a result, we have the expertise to solve the most challenging supply chain constraints.

Partner with Federal Electronics

Contact us today to learn more about our solutions that are designed to drive your success.